The KFE has manhole covers and truck manufactured in accordance with European and international standards EN and with ADR. The models SK4500Al and SK4500St overlap in the mean overall requirements Drop Test as specified in European Standard EN13317, EN13314 and EN14596.

SK4500Al – Ø 500mm ADR Aluminum Manhole Cover Assembly

Product Description

Based on the experience of KALYMNOS in producing liquid fuel transport equipment, the SK4500Al manhole cover, covers the demands of the ADR regulations and offers unrivalled safety and operational features.

– Robust Construction of the assembly exceeds the requirements of the EN DROP TEST (EN 13317:2002).

– 24 Bold Fixing Ø 9.5mm on Ø530 PCD covers the demands of EN13317:2002/A1.

– Pressure/Vacuum breather vent with integrated rollover protection against spillage.

– Emergency pressure relief valve to eliminate the excess pressure in the tank compartment in case of fire. Designed and tested in accordance to EN14596:2005 and EN13314:2002. Relieving pressure set at 280 mbar and emergency venting capacity of 6500m3/h, of air at 350 mbar.

– Two stages opening eliminates danger due to residual compartment pressure before fully opening of the fill cover.

– Cross Arm Reinforcements under the baseplate increase the rigidity of the assembly.

– Integrated Locking mechanism eliminates the danger of accidental opening meets the requirements of the NTTC DOT 406 (49CFR 178.345-5).

– Accessory Ports for the installation of Dipstick, Vapour Recovery Vent and Overfill Sensor.

Technical Data

P/V vent set pressure: 100 mbar

P/V vent vacuum set: 10 mbar

Manhole assembly weight: 13.5kg

Emergency pressure set: 280 mbar

Emergency venting capacity: 6500m3/h at 350 mbar

Downloads

SK4500Al – Ø 500mm ADR Aluminum Manhole Cover Assembly 780.25 KB 102 downloads

Video Data

SK4500ST – Ø 500mm ADR Mild Steel Manhole Cover Assembly

Product Description

Based on the experience of KALYMNOS in producing liquid fuel transport equipment, the SK4500St manhole cover, covers the demands of the ADR regulations and offers unrivalled safety and operational features. – Robust Construction of the assembly exceeds the requirements of the EN DROP TEST (EN 13317:2002).

– 24 Bold Fixing Ø 9.5mm on Ø530 PCD covers the demands of EN13317:2002/A1.

– Pressure/Vacuum breather vent with integrated rollover protection against spillage.

– Emergency pressure relief valve to eliminate the excess pressure in the tank compartment in case of fire. Designed and tested in accordance to EN14596:2005 and EN13314:2002. Relieving pressure set at 280 mbar and emergency venting capacity of 6500m3/h, of air at 350 mbar.

– Two stages opening eliminates danger due to residual compartment pressure before fully opening of the fill cover.

– Cross Arm Reinforcements under the baseplate increase the rigidity of the assembly.

– Integrated Locking mechanism eliminates the danger of accidental opening meets the requirements of the NTTC DOT 406 (49CFR 178.345-5).

– Accessory Ports for the installation of Dipstick, Vapour Recovery Vent and Overfill Sensor.

Technical Data

P/V vent set pressure: 100 mbar

P/V vent vacuum set: 10 mbar

Manhole assembly weight: 16.5kg

Emergency pressure set: 280 mbar

Emergency venting capacity: 6500m3/h at 350 mbar

Downloads

SK4500ST – Ø 500mm ADR Mild Steel Manhole Cover Assembly 792.79 KB 80 downloads

Video Data

The Kalymnos Fuel Engineering has manhole covers and truck made in accordance with the American standard DOT MC406. Available in sizes 16 “and 20″ and there are versions for installation with screws or screw tightened. All manhole cover are equipped with SK3250 fill hole cover.

SK3400C – Ø 16” (400mm) Manhole Cover Assembly

Product Description

Based on the experience of KALYMNOS in producing liquid fuel transport equipment, the SK3400C manhole cover, covers the demands of the DOT 49CFR §178.345-5 regulation and offers unrivalled safety and operational features.

– Robust Construction of the assembly exceeds the requirements of the TTMA RP No. 81-02 Dynamic Pressure Surge Test.

– Clump Fixing tested for liquid tightness at 250 kPa (36 psig).

– Pressure/Vacuum breather vent with integrated rollover protection against spillage.

– Emergency pressure relief valve to eliminate the excess pressure in the tank compartment in case of fire. Designed and tested in accordance to DOT 49CFR §178.345-5 and DOT 49CFR §178.346-3. Relieving pressure set at 230 mbar and emergency venting capacity of 2800m3/h, of air at 300 mbar.

– Two stages opening eliminates danger due to residual compartment pressure before fully opening of the fill cover.

– 20” option available as SK3500C.

– Aluminium cover plate available for reduced weight.

– Integrated Locking mechanism available as optional, eliminates the danger of accidental opening meets the requirements of the NTTC DOT 406 (49CFR 178.345-5).

– Accessory Ports options available for the installation of Dipstick. None to 3 ports can be offered for Dipstick, Sensor and Vapour Vent.

Technical Data

P/V vent set pressure: 100 mbar

P/V vent vacuum set: 10 mbar

Manhole assembly weight: 10.2kg

Emergency pressure set: 230 mbar

Emergency venting capacity: 2800m3/h at 300 mbar

Downloads

SK3400C – Ø 16” (400mm) Manhole Cover Assembly 773.84 KB 29 downloads

Video Data

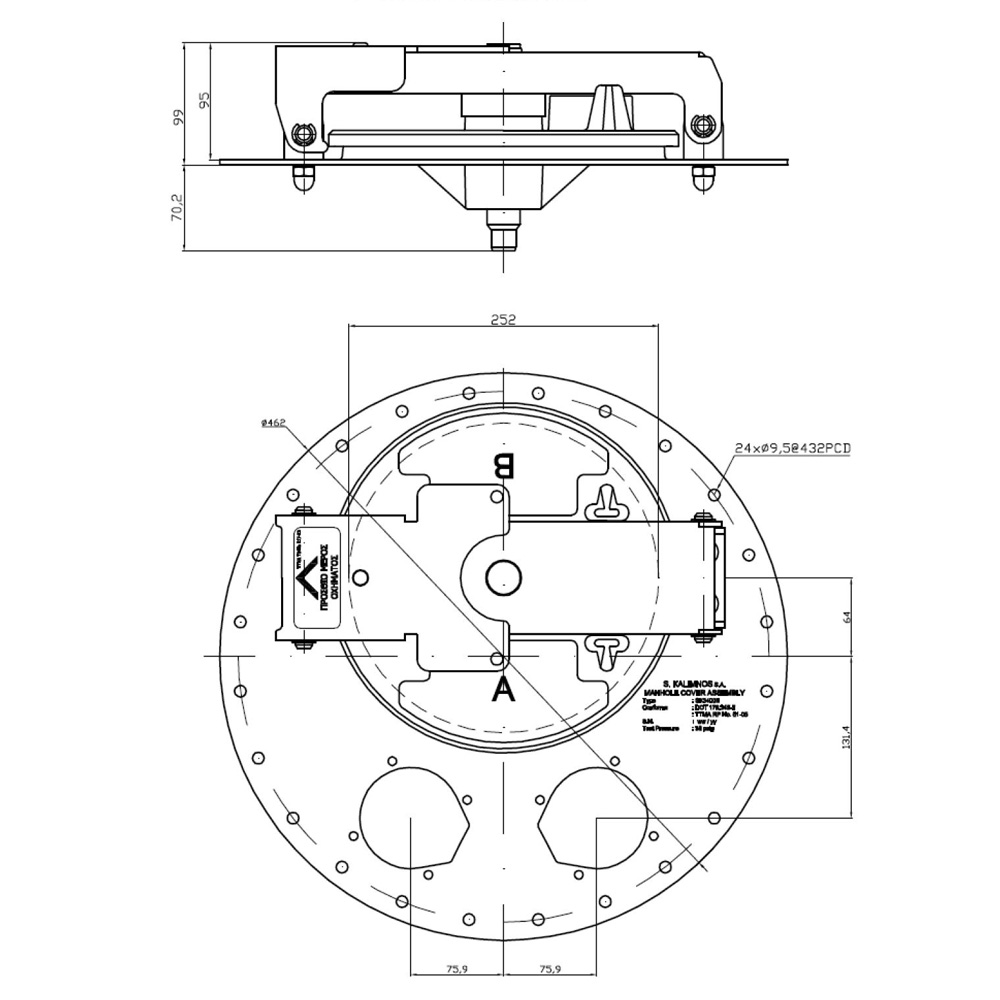

SK3400B – Ø 16” (400mm) Manhole Cover Assembly

Product Description

Based on the experience of KALYMNOS in producing liquid fuel transport equipment, the SK3400B manhole cover, covers the demands of the DOT 49CFR §178.345-5 regulation and offers unrivalled safety and operational features.

– Robust Construction of the assembly exceeds the requirements of the TTMA RP No. 81-02 Dynamic Pressure Surge Test.

– 24 Bold Fixing Ø 9.5mm on Ø432 PCD tested for liquid tightness at 250 kPa (36 psig).

– Pressure/Vacuum breather vent with integrated rollover protection against spillage.

– Emergency pressure relief valve to eliminate the excess pressure in the tank compartment in case of fire. Designed and tested in accordance to DOT 49CFR §178.345-5 and DOT 49CFR §178.346-3. Relieving pressure set at 230 mbar and emergency venting capacity of 2800m3/h, of air at 300 mbar.

– Two stages opening eliminates danger due to residual compartment pressure before fully opening of the fill cover.

– Galvanized Steel crossarm pins for rust-free service.

– Aluminium cover plate available for reduced weight.

– Integrated Locking mechanism available as optional, eliminates the danger of accidental opening meets the requirements of the NTTC DOT 406 (49CFR 178.345-5).

– Accessory Port for the installation of Dipstick, Vapour Recovery Vent and Overfill Sensor.

Technical Data

P/V vent set pressure: 100 mbar

P/V vent vacuum set: 10 mbar

Manhole assembly weight: 10.8 kg (St) / 8.9 kg (Al)

Emergency pressure set: 230 mbar

Emergency venting capacity: 2800m3/h at 300 mbar

Downloads

SK3400B – Ø 16” (400mm) Manhole Cover Assembly 790.48 KB 28 downloads

Video Data

KFE produces and offers a complete range of tanks welding neck for placing manholes. Available variants neck accordance with standard EN13094 and other international standards. The construction can be done in Aluminum, Steel and Stainless Steel. Special equipment is also available upon request.

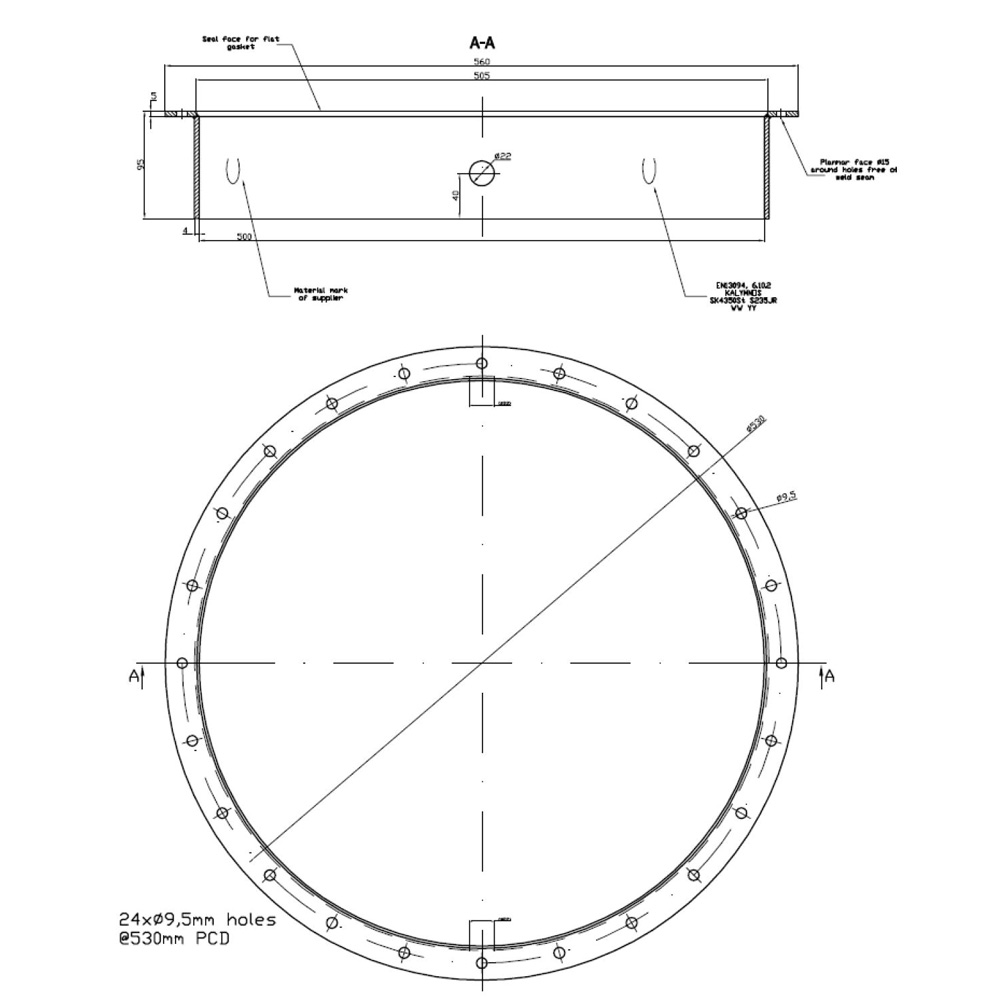

SK4350Al – Ø 500mm Aluminum ADR Weld Neckring

Product Description

The SK4350Al aluminum weld neckring, covers the demands of the ADR EN13094:2008 and EN13317:2001 regulations and offers unrivalled design and installation features.

– 24 Bold Fixing Ø 9.5mm on Ø530 PCD covers the demands of EN13317:2002/A1.

– EN AW5182-H111 Aluminum Sheet of 6mm covers the thickness criteria of EN13094:2008

– Vent Opening allows the safe filling of the tank compartment to the maximum capacity.

– Marking of each individual neckring assures the tank builder for the quality and traceability of the installed material.

– Wide Flat Sealing Surface allows for correct sealing and proper installation of the manhole cover assembly.

– Suitable for Aluminum ADR Class 3 tanks for carrying dangerous goods with a vapour pressure not exceeding 110kPa@50oC (absolute pressure).

Technical Data

Material: EN AW5182-H111

Design Pressure: 250 kPa

Thickness: 6 mm

Internal Diameter: 500 mm

Downloads

SK4350Al – Ø 500mm Aluminum ADR Weld Neckring 611.87 KB 31 downloads

Video Data

SK4350St – Ø 500mm Steel ADR Weld Neckring

Product Description

The SK4350St steel weld neckring, covers the demands of the ADR EN13094:2008 and EN13317:2001 regulations and offers unrivalled design and installation features.

– 24 Bold Fixing Ø 9.5mm on Ø530 PCD covers the demands of EN13317:2002/A1.

– S235JR Steel Sheet of 5mm on top and 4mm on the sides covers the thickness criteria of EN13094:2008

– Vent Opening allows the safe filling of the tank compartment to the maximum capacity.

– Marking of each individual neckring assures the tank builder for the quality and traceability of the installed material.

– Wide Flat Sealing Surface made from thicker steel allows for correct sealing and proper installation of the manhole cover assembly.

– Suitable for Steel ADR Class 3 tanks for carrying dangerous goods with a vapour pressure not exceeding 110kPa@50oC (absolute pressure).

Technical Data

Material: S235JR

Design Pressure: 250 kPa

Thickness: 5 mm (top) 4 mm (sides)

Internal Diameter: 500 mm

Downloads

SK4350St – Ø 500mm Steel ADR Weld Neckring 641.44 KB 17 downloads

Video Data

Necessary equipment for all tank vehicles in Class 3, valves and breathing SK2100 SK3100 exceed the requirements of the standard EN14595 and provide the necessary protection to the B / O both during normal operation and in emergency situations.

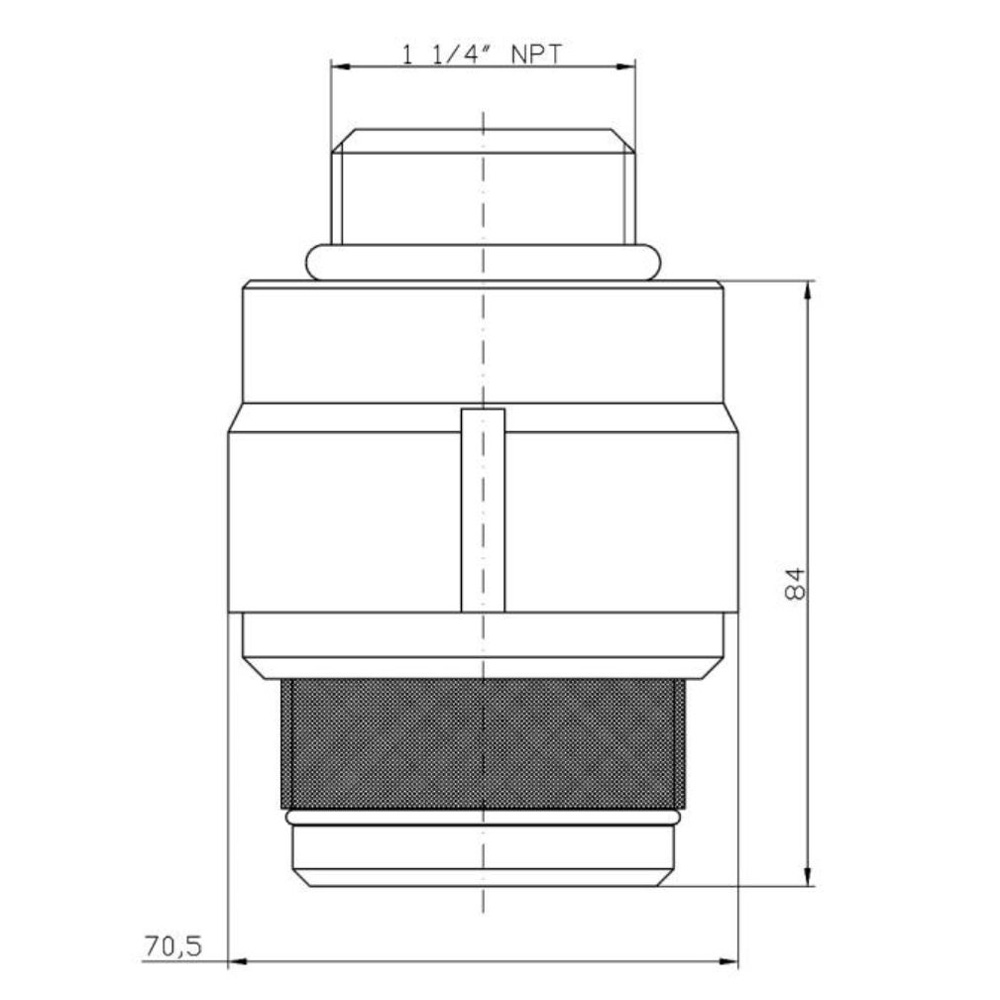

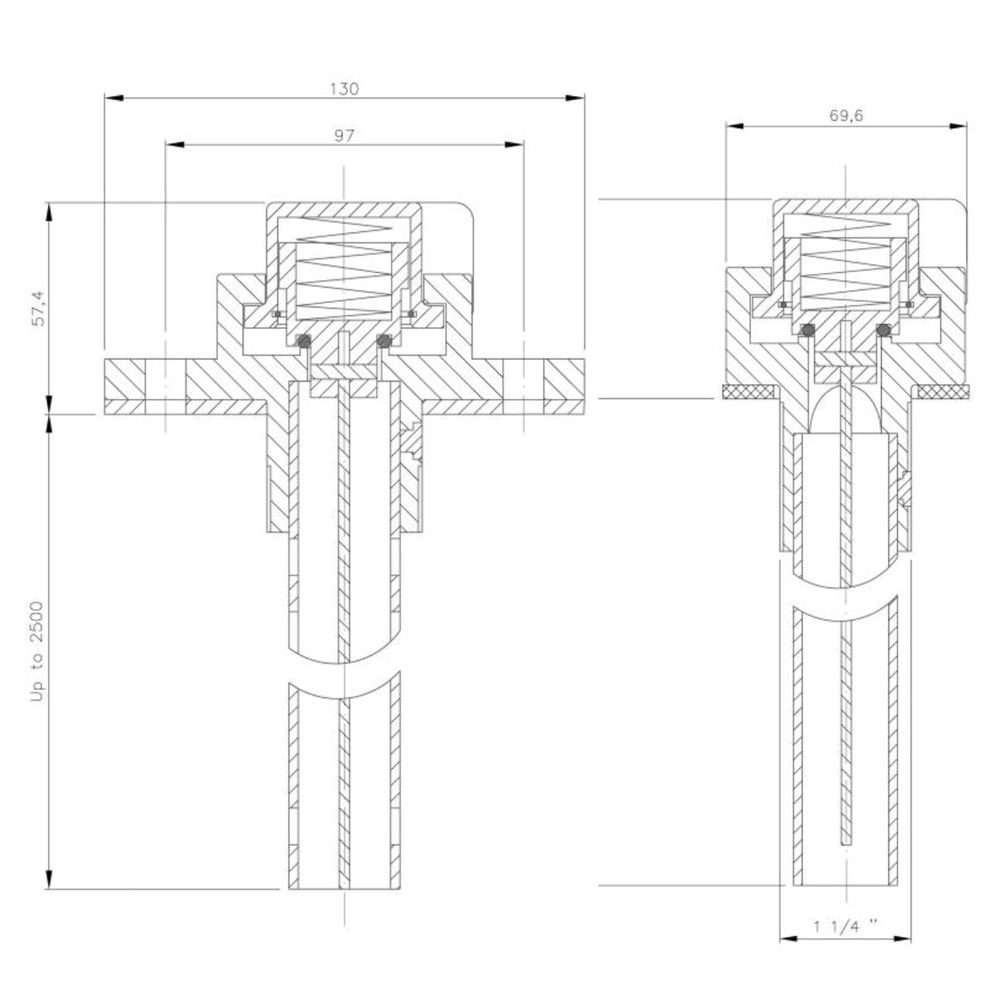

SK3100 – 1¼” Pressure and Vacuum Breather Vent

Product Description

Incorporated in all SK3000 & SK4500 series manhole cover assemblies and available also separately, the 1¼” SK3100 Pressure and Vacuum Breather Vent provides breathing for tankers including roll over spillage protection.

– Robust Construction of the assembly exceeds the requirements of EN DROP TEST (EN 14595:2002).

– Conforms EN 14595:2005 European standard in design and construction.

– Flame Trap Strainer for the prevention of the flame passage.

– High Flow through the 1¼” airways. Rated venting capacity of 100 m3/h at 30 kPa overpressure and 20 m3/h at 3 kPa vacuum.

– Overturn Protection through seal off valve.

– Viton Seals are standard for compatibility with unleaded petrol.

– Relieving Pressure settings selection available depending on any special needs. Coming as standard to 10kPa pressure – 1kPa vacuum relief.

– 1¼” NPT and BSP connections for compatibility with a wide range of manhole cover assemblies.

– 8 bold on 130mm PCD fixing.

Technical Data

P/V vent set pressure: 100 mbar

Overpressure venting capacity: 100 m3/h at 300 mbar

P/V vent vacuum set: 10 mbar

Vacuum venting capacity: 20 m3/h at 30 mbar

P/V vent weight: 0.54 kg

Downloads

SK3100 – 1¼” Pressure and Vacuum Breather Vent 644.39 KB 39 downloads

Video Data

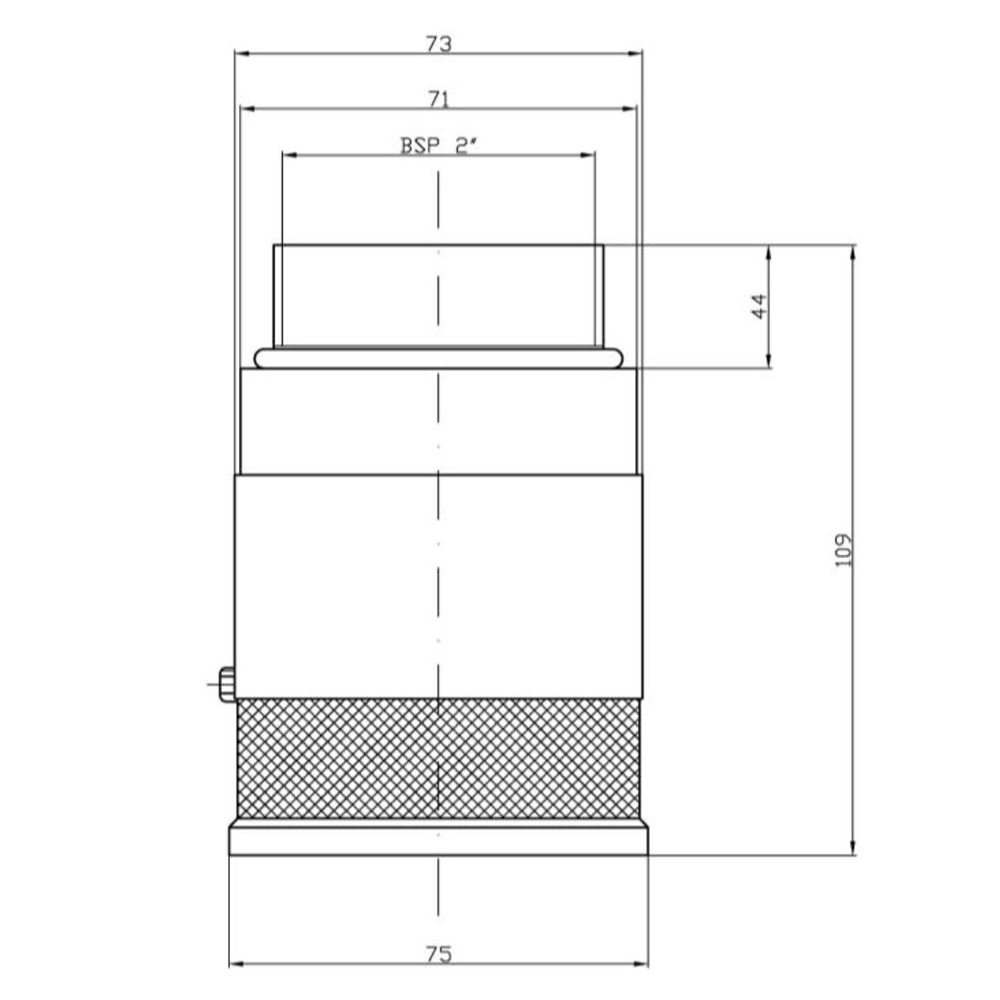

SK2100 – 2″ Pressure and Vacuum Breather Vent

Product Description

Incorporated in all SK3000 & SK4500 series manhole cover assemblies and available also separately, the 2” SK2100 Pressure and Vacuum Breather Vent provides breathing for tankers including roll over spillage protection.

– Robust Construction of the assembly exceeds the requirements of EN DROP TEST (EN 14595:2002).

– Conforms EN 14595:2005 European standard in design and construction.

– Flame Trap covering the requirements of the LGBF class.

– High Flow through the 2” airways. Rated venting capacity of 250 m3/h at 30 kPa overpressure and 80 m3/h at 3 kPa vacuum.

– Overturn Protection through seal off valve.

– Viton Seals are standard for compatibility with unleaded petrol.

– Relieving Pressure settings selection available depending on any special needs

– 2’’ BSP for installation in SK3000 & SK4500 series manhole cover fillcap.

– 8 bold on 130mm PCD fixing.

Technical Data

P/V vent set pressure: 100 mbar

Overpressure venting capacity: 250 m3/h at 300 mbar

P/V vent vacuum set: 10 mbar

Vacuum venting capacity: 80 m3/h at 30 mbar

P/V vent weight: 0.6 kg

Downloads

SK2100 – 2″ Pressure and Vacuum Breather Vent 649.14 KB 29 downloads

Video Data

Necessary in each compartment for reliable level control, the KFE has mechanical volumetric rods made from high quality anodised aluminum with simple and reliable locking mechanism. Available in lengths from 1m to 3m.

SK2200B|SK2200T – Aluminum Gauging Dipstick

Product Description

Durable construction of aluminium alloy along with anodized replaceable sticks make the SK2200 Dipstick assembly the simplest solution for accurate physical measuring of the tank’s content. It comes in two variants SK2200B for bold fixing and SK2200T for threaded fixing.

– Durable Construction of the body made of aluminium alloy.

– Bolded or Threaded fixing available.

– Anodized aluminium replaceable measuring sticks.

– Spring Loaded sealing mechanism.

– Drop Test approved for safety in case of tank overturn.

– Easy Installation – fits in the standard accessory ports of the SK3000 & SK4500 manhole cover series

Technical Data

SK2200T 2m long Threaded Dipstick Assembly: 1.6kg

SK2200B 2m long Bolded Dipstick Assembly: 1.8kg