MATEC® GROUP has been present on the National and International territory for over 30 years, with its divisions COMPOTEC®, ENCO®, FARIVO®, TOPFLEX® and INDUSTRIALE. With an ISO 9001:2000 accreditation MATEC® GROUP focus on the design, development and manufacture of Flexible hoses and fittings. The product range includes Flexible Composite hoses, Flexible metallic hoses, Flexible Rubber hoses, in addition we manufacture and market Metallic Expansion joints and an extensive range of couplings and fittings for low and medium pressure, associated components together with the distribution of engineered products for industrial maintenance.

MATEC® GROUP operates directly in Italy, through a network of technical engineers, salesmen and Depots, and outside Italy through a net of specialized Distributors, all over the world.

For years the name COMPOTEC® has been synonymous with special hoses for the Petroleum and Chemical Industry. Compotec® hose is light, strong, highly flexible, anti-static and kink-proof. Yet it’s extremely durable thanks to the tensioned internal and external steel wire spirals, which give great strength. Compotec® offers the most extensive and varied composite hose range for an extremely wide range of applications. Precision engineered end fittings complete the range. Boasting a temperature range of – 200°C (Cryotec hose), to + 200°C (Hitemp hose) and pressure ratings of 10, 15 and up to 40 bar for special types, COMPOTEC® hoses are lined with either Polypropylene or PTFE, giving the hose excellent resistance to solvents, chemicals, acids, resins, and petroleum based products.

For further information, you may visit Matec Group website

Oil & Fuels

Product Description

COMPOTEC® OIL is a multi-layer thermoplastic hose manufactured from Polypropylene, Polyethylene and Polyester films and Polypropylene fabrics, with a weatherproof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in ELASTOTHANE®, a special PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers superior temperature and abrasion characteristics.

All the different layers are wrapped together and tensioned between internal and external wire spirals. This enables our product to meet the requirement of the Petrol-chemical industry and those of the Oil & Gas industry.

COMPOTEC® assemblies are fitted with an extensive range of couplings readily available, externally swaged with crimping ferrules.

COMPOTEC® OIL assemblies are tested at 1 1⁄2 times rated working pressures for safety and reliability, in accordance with EN ISO 1402 (BS 5842:1980 clause 6.4). The securing ferrule, at one end of the hose, is permanently marked by engraving, with manufacturer’s name, nominal bore, the hose assembly serial number and the test date. The marking of hose assemblies is made in compliance with PED Directive (97/23/ CE). Full test certification can be supplied on request.

COMPOTEC® OIL hoses can be supplied in the FIRETEC version with ADR selfestinguish CL1 cover. Burst pressure indicated, is at ambient temperature when tested in accordance with EN ISO 1402 (BS 5173 section 102.10:1990). Electrical continuity is achieved by the two wires bonded to the end fittings, this helps dissipate accumulated charge and to avoid static flash. The electric resistance of hose assemblies is less than 1 ohm/mt, as required by EN ISO 8031:2009 – 4.7. Upon request it’s possibile to manufacture COMPOTEC® hoses in accordance to the Directive 94/9/EC “ATEX”, with a special outer antistatic black cover, ground connection cable, for explosive environment.

COMPOTEC® OIL 800 HD and OIL SD hoses are specially engineered for the transfer of hydrocarbons, including oil, petrol, diesel, lubricating oils, MTBE, paraffin and 100% aromatics, in all kinds of transfer.

Available Versions

EN 13765:2015 Type 1: Vaporoil – Light Duty

EN 13765:2015 Type 2: Oil SD – Standart Duty

EN 13765:2015 Type 3: Oil 800 HD – Heavy Duty

Downolads

[wpdm_package id=3083 template=”57d7af918045b”]

Video Data

Chemicals

Product Description

COMPOTEC® CHEM is a multi-layer thermoplastic hose manufactured from Polypropylene, Polyethylene and Polyester films and Polypropylene fabrics, with a weather-proof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in ELASTOTHANE®, a special PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers superior temperature and abrasion characteristics.

All the different layers are wrapped together and tensioned between internal and external wire spirals. This enables our product to meet the requirement of the Petrol-chemical industry and those of the Oil & Gas industry.

COMPOTEC® CHEM assemblies are fitted with an extensive range of couplings readily available, externally swaged with crimping ferrules.

COMPOTEC® CHEM assemblies are tested at 1 1⁄2 times rated working pressures for safety and reliability, in accordance with EN ISO 1402 (BS 5842:1980 clause 6.4). The securing ferrule, at one end of the hose, is permanently marked by engraving, with manufacturer’s name, nominal bore, the hose assembly serial number and the test date. The marking of hose assemblies is made in compliance with PED Directive (97/23/ CE). Full test certification can be supplied on request.

COMPOTEC® CHEM hoses can be supplied in the FIRETEC version with ADR self-estinguish CL1 cover. Burst pressure indicated, is at ambient temperature when tested in accordance with EN ISO 1402 (BS 5173 section 102.10:1990). Electrical continuity is achieved by the two wires bonded to the end fittings; this helps dissipate accumulated charge and to avoid static flash. The electric resistance of hose assemblies is less than 1 ohm/mt as required by EN ISO 8031:2009 – 4.7. Upon request it’s possibile to manufacture COMPOTEC® CHEM hoses in accordance to the Directive 94/9/EC “ATEX”, with a special outer antistatic black cover and ground connection cable, for explosive environment.

COMPOTEC® CHEM 700 HD and CHEM SD are chemically compatible and mechanically engineered to handle a wide range of hazardous chemicals. Extremely flexible, easy to handle and bend, all hoses are 100% aromatic resistant, antistatic and can be used for suction or discharge. Vacuum rating is 0,9 bar, according to the EN ISO 7233 method B.

Available Versions

EN 13765:2015 Type 1: Vaporchem – Light Duty

EN 13765:2015 Type 2: Chem SD – Standart Duty

EN 13765:2015 Type 3: Chem 700 HD – Heavy Duty

Downolads

[wpdm_package id=3088 template=”57d7af918045b”]

Video Data

Hitemp - Bitumen

Product Description

CONSTRUCTION: COMPOTEC® HITEMP 305 is a multi-layer thermoplastic hose designed around several Fluoropolymer liners, supported by a Stainless Steel inner wire, and reinforced with films and fabrics specifically designed for high temperature applications. All the different layers are wrapped together and tensioned between internal and external wire spirals.

COMPOTEC® HITEMP 305 utilizes the new PTFE laminate film NANOTEC®, obtained with the latest and highest standard of Nanotechnology, ensuring unique mechanical strength and ZERO porosity, NANOTEC® technology is a Patented Design exclusive and unique, belonging to MATEC GROUP. Includes in the construction an FEP seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction Outer cover is made in ELASTAR, a special High temperature resistant PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers as well superior abrasion resistance characteristics. Available in 40 mt coils from 3/4” to 4” and 25 mt length up to 12”.

APPLICATIONS: COMPOTEC® HITEMP 305 is specifically designed as an hose for the transfer of HOT OIL and BITUMEN under positive or negative pressures, HITEMP 305 hose are used in such applications as transfer for rail and road tanker loading and unloading, storage tank and in-plant use. Extremely flexible, easy to handle and bend, even at very high or very low outdoor temperatures. All hoses are 100% aromatic resistant, antistatic and can be used for suction or discharge. Vacuum rating is 0,9 bar, according to the EN ISO 7233 method B. Thanks to the inner PTFE NANOTEC® construction, nothing sticks to the inner wall of the hose, and due to absence of inner corrugations or convolutions, (smooth body), nothing will remain trapped in it.

COMPOTEC® HITEMP 305 hoses can be supplied in the FIRETEC version to meet the Fire retardand performance criteria acc. to European Standards EN 13765:2010 Normative, Annex G, and with ADR self-estinguish CL1 characteristics. The special series of HITEMP 305 FIRETEC hoses, are mainly used for cooling application in the Steel industry.

Available Versions

EN 13765:2015 Type 4:

Hitemp 305

Hitemp Firetec STD

Hitemp Firetec Glass

Hitemp Firetec Pirojacket

Hitemp Twinhose

Downolads

[wpdm_package id=3097 template=”57d7af918045b”]

Video Data

Higrade - Aircraft Refuelling

Product Description

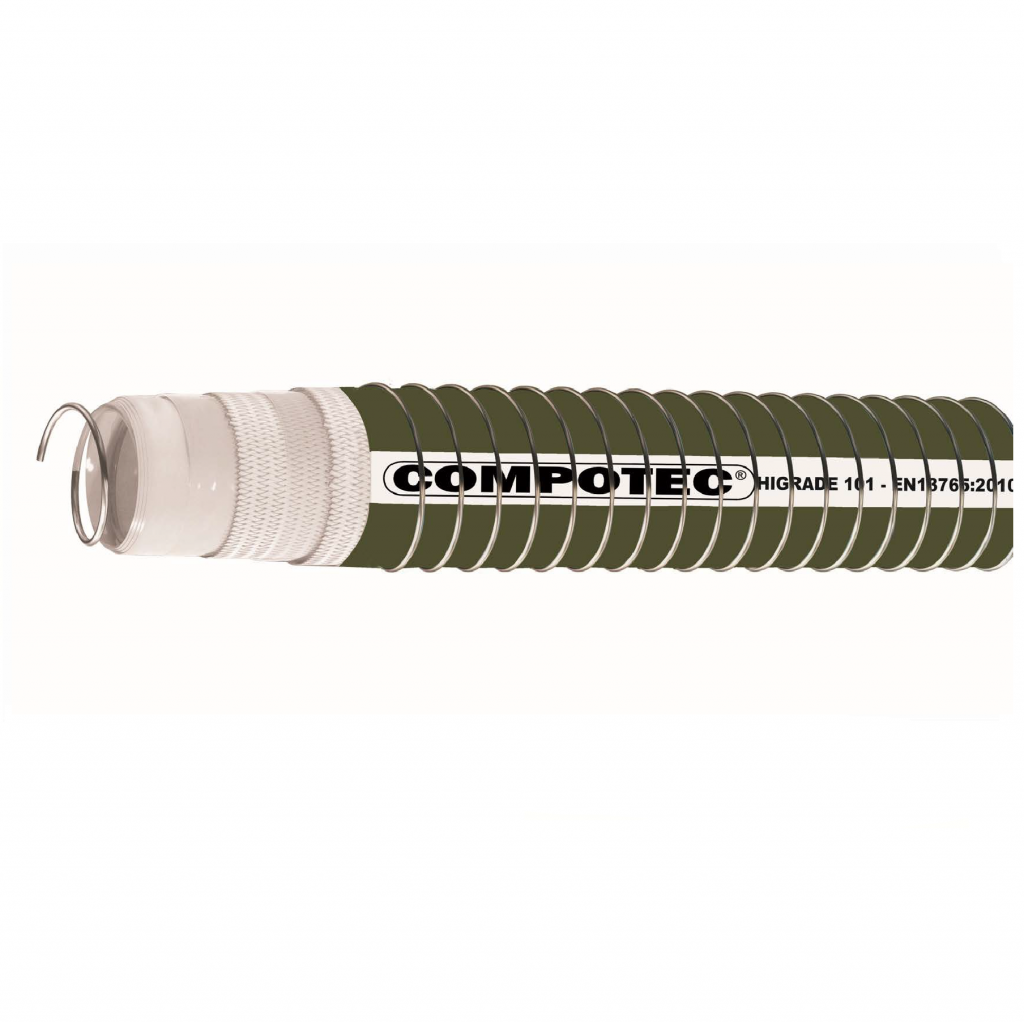

COMPOTEC® HIGRADE 101 hose it’s an High purity Fuel hose.

Multi-layer thermoplastic hose manufactured from Polypropylene, Polyester and Polyethylene films and Polypropylene fabrics, with a weather-proof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in ELASTAR, a special PU coated fabric; its UV, Ozone, Sunlight and weathering resistance, offers superior temperature and abrasion

characteristics.

All the different layers are wrapped together and tensioned between internal and external wire spirals. This enables our product to meet the requirement of the Petrol-chemical industry and those of the oil tank truck industry.

COMPOTEC® HIGRADE 101 is manufactured according to the requirementspecified by the European Standards EN 13765:2010 Type 3 (BS 5842:1980), and in accordance with Australian Standards AS 2683. Complies the recommendations of NAHAD Guidelines (NAHAD 600/2005).

Specifically designed for the transfer of special Aviation fuels, Jet Fuel

(JET A-1 and JP-6), Jet biofuels, Synthetic jet fuel (SPK) or Aviation Turbine fuel (ATF).

Manufactured with special procedures, designed to eliminate any contaminants, COMPOTEC® HIGRADE 101 hoses fully complies BS 3492:1987 for carrying gasoline, kerosene, fuel and lubrication oils, including aviation fuels with high aromatic content at a temperature up to 100°C. Bore material (first layer in contact with fluid) is made in an high purity, Ultra High MolecularWeight Polyethylene (UHMW PLT) to avoid any possible absorption or contamination. Stainless steel inner wire is included to ensure that no metallic flakes are deposited into the conveyed products. During all the phases of production, the

hose is controlled and no lubricants or oils are used in the manufacturing process. Extremely flexible, easy to handle and bend, COMPOTEC® HIGRADE 101 hoses are used in such applications as transfer, loading and discharging, storage tank and in-plant use, all hoses are 100% aromatic resistant and perfectly antistatic and can be used for delivery or suction of vapours. COMPOTEC® HIGRADE 101 assemblies are fitted with an extensive range of couplings readily

available, externally swaged with Stainless Steel or Aluminium ferrules.

Jet fuel or aviation turbine fuel (ATF) is a type of aviation fuel designed for use in aircraft powered by gas turbine engines. It is colourless to straw-colored in appearance. The most commonly used fuels for commercial aviation are Jet A and Jet A-1, which are produced to a standardized international specification. The only other jet fuel commonly used in civilian turbine-engine powered aviation

is Jet B, which is used for its enhanced cold-weather performance.

Available Versions

EN 13765:2015 Type 2: Higrade SD

EN 13765:2015 Type 3: Higrade 101 HD

Downolads

[wpdm_package id=3100 template=”57d7af918045b”]

Video Data

Food

Product Description

COMPOTEC® FOOD 500 is a multi-layer thermoplastic hose designed

around several Ultra High Molecular Weight Polyethylene (UHMW PLT) liners, supported by 316 L Stainless Steel inner and outer wires, with a weather-proof and abrasion resistant outer cover made of Polyvinyl coated Polyester fabric. Outer cover is also available in ELASTAR, a special PU coated fabric with extra UV, Ozone, Sunlight and weathering resistance, offering superior temperature and abrasion characteristics.

Extremely flexible, easy to handle and bend, FOOD 500 hose complies with International regulations, for all the application in direct contact with food. During all the phases of production, the hose is controlled in an high purity process of manufacture. No oils or lubrificants are used during the process to avoid any possible contamination.

With its Heavy Duty construction, includes in the construction an High Density PLT seamless tubular extruded film, to avoid any possible leak and guarantee a gas-tight construction. All the different layers are wrapped together and tensioned between internal and external wire spirals. It is possible to clean FOOD 500 with loose steam or with various chemicals (diluted caustic soda and nitric) without any problem. All hoses are 100% antistatic and can be used for suction or discharge. Vacuum rating is 0,9 bar, according to the EN ISO 7233 method B.

COMPOTEC® FOOD 500 assemblies are fitted with an extensive range of couplings readily available, including Sanitary type fittings, DIN, SMS, RYT or Tri-Clamp, externally swaged with Stainless Steel ferrules.

Available Versions

EN 13765:2015 Type 3:

Food 500 UHMW inside

AbraFood Polyurethane inside

FoodFlow Nanotec®

Downolads

[wpdm_package id=3108 template=”link-template-calltoaction3.php”]

Video Data

COMPOTEC® MARINE OFFSHORE hoses are multi-layer thermoplastic hoses, and can be used both, for FLOATING, or SUBMARINE applications. Both types can withstand the high demand of offshore installations. COMPOTEC® MARINE OFFSHORE hose is the first Composite offshore hose for CHEMICAL, OIL & CRYOGENIC applications. They are produced following the requirements of the Oil Companies International Marine Forum publication “Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings”. All COMPOTEC® MARINE OFFSHORE hoses are Heavy Duty construction, and according to the suggestion and recommendations of EU Port Authorities.