MannTek is a coupling manufacturer. Produces and markets products for safe and environmentally friendly handling of aggressive fluids for the chemical and petrochemical industries. MannTek, Mann Teknik AB, is a Swedish limited liability company located in Mariestad, Sweden.

The main product is the Dry Disconnect Couplings STANAG 3756, DDCouplings®, for spill free liquid handling. The products are marketed through independent representatives in more than 30 countries.

MannTek have many years of experience in designing, producing and marketing of DDCouplings ® all since 1977.

Dry Disconnect Couplings are available in sizes from ¾” up to 6” and in a wide range of materials and seals to be the given choice for almost any application. The self sealing design of the Dry disconnect couplings guarantees both the highest level of safety and also the quickest way of connecting and disconnecting. Mann Tek has knowledge from design, production and marketing of DDCouplings® since 1977.

DDCouplings®, Dry Disconnect Couplings, are designed for quick and spill free connection and disconnection of hoses and pipelines. They are used by producers of ink, adhesives, fatty acids, pharmaceuticals, liquid soaps, petroleum, chemicals, agricultural and a wide variety of caustic products and speciality acids.

DDCouplings® are especially needed in areas of zero tolerance spillage when your product:

- is of high value

- requires costly environmental methods of cleaning-up in case of spillage

- is expensive to reprocess or dispose of

- is hazardous to the environment

- can cause a health risk

- is prone to accidental spillage and product loss

DDCouplings® are in use in installations all over the world, especially where certification is a prerequisite and are certified by TÜV, Apragaz, Veritas, TDT, plus regionally required approvals.

Tank unit with integrated shut-off valve, to STANAG 3756. Self locking quick connect/disconnect coupling for liquid media (Stainless Steel also for various gases). Spillfree connection without tools.

Typically fix mounted as filling connector on storage tanks, mobile tanks like IBC and ISO containers, road tankers, rail tank containers and ship manifolds.

Can be coupled up to 7 bar. Working pressure see additional info. Temperature range – 20° C up to + 80° C; fulfilment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

Female (Hose Unit, Coupler)

Hose unit with swivel, with integrated shut-off valve, to STANAG 3756. Self locking quick connect/disconnect coupling for liquid media (Stainless Steel also for various gases). Spillfree connection without tools.

Typically mounted on hose assemblies and loading arms for temporary connection between storage tank and mobile transport unit for loading and unloading.

Can be coupled up to 7 bar. Working pressure see additional info. Temperature range – 20° C up to + 80° C; fulfilment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

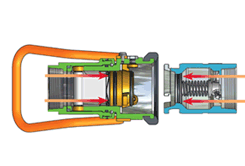

Safety Break-away couplings are used to prevent pull away accidents, protect terminal and loading/unloading equipment and eliminated unwanted product release. The break-away couplings has a diverted breaking point which will break at a determined break-load where upon the internal valves will automatically close on both sides. This will in a longer time frame minimize down time, save money, equipment and the environment.

The Safety Break-away couplings are available as Industrial and Marine type.

How it works – before and after emergency disconnect

Non-axial forces concentrate the tension forces more strongly on one bolt, so that the safety break-away coupling reacts in a natural way to the reduction of the hose break forces.

Before emergency disconnect

The safety break-away valve consists of two halves, each with a valve that has a o-ring seal.

After emergency disconnect

After emergency disconnect

When the SBCouplings separate, it allows the valves to close. The two valves closes rapidly, minimizing exposure to

FEATURES

- Passive security against situations where a hose or loading arm could be subjected to inadvertent excessive loads.

- Design features are a simple mechanism and no loose components which could belost after release.

- Operates independently of shut off safety system and does not require an externalpower source.

- Easy to reset on site with one person High flowrate / low pressure drop

- Very low loss, positive shut-off of both coupling halves results in minimum product loss.

- Lightweight and robust design.

- Available with ANSI/DIN flanges or threaded (BSP or NPT).

Breakaway coupling with integrated shut-off valves. Used to protect hose assemblies and loading arms against excessive loads.

Designed with breaking bolts to be able to activate with a tensile force on the transfer line being applied at an angle to the plane of the coupling housing, up to 90 degrees.

Suitable for all common liquid and gaseous media in all industrial product transfer installations.

Working pressure see additional info. Temperature range -20° C up to +80° C; fulfilment of larger temperature range -50° C up to +200° C is possible – depending on medium, coupling and seal material.

Typically installed between two hose assemblies, release by axial pull only.

Breakaway coupling with integrated shut-off valves. Used to protect hose assemblies and loading arms against excessive loads. Designed with breaking bolts to be able to activate with a tensile force on the transfer line

being applied axially to the plane of the coupling housing. This coupling has additional external features that provide increased resistance to bending moment forces which may be applied to the coupling,

preventing premature activation in the unpredictable marine environment. Suitable for all common liquid and gaseous media. Typical applications include ship to offshore platform, and ship to ship product transfer operations.

Working pressure see additional info. Temperature range – 20° C up to + 80° C; fulfilment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

Typically used when a tensile force on the transfer line is not allowed or very low separation forces are required.

Additionally, release forces are almost independent from operating pressure; SBC-C are specially recommended in transfer systems with the combination of high operating pressure and weak piping structure. Breakaway coupling with integrated shut-off valves. Used to protect hose assemblies and loading arms against excessive loads.Designed with a clamp system where the tensile force is not transmitted via the hose or the loading arm but by an integrated cable which is attached to a fixed point.

After the admitted travel limit of the cable is reached (angle up to 90 degrees), only a small pull is sufficient to actuate the separation.

The necessary force is nearly independent from the internal pressure. Suitable for all common liquid and gaseous media.

Typical applications in all industrial product transfer installations Working pressure see additional info.

Temperature range – 20° C up to + 80° C; fulfillment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

Swivel Joints are used in the industry wherever a movable pipe-connection system between two equipment parts is needed. Avoiding one of the biggest causes of premature hose failure. Torque stress is the largest single cause of PTFE and Stainless steel convoluted hose failure.

The swivel joints are designed for slow rotary motions under the influence of high internal pressures and/or external stress such as traction and bending forces. With an appropriate combination of swivel joints nearly all movements from the simple rotation or swivelling motion up to motional actions in space can be realized.

Technical information

Sizes

¾” (DN20) to 10” (DN200)

Maximum Working pressure

MWP PN 10-125 bar

MAWP 150-1800 psi

Materials

Aluminium, Brass, Stainless steel,

Hastelloy, Titanium. Others on request.

Connections

Female and Male BSP / NPT, flanged DIN

and ANSI. Others on request.

Hose Swivels - single ball bearing

Compact swivel, to allow free rotation of a handling device to protect a hose from torsion.

Typically mounted at the end of the hose where handling equipment without integrated swivel is attached.

Suitable for all common liquid and gaseous media in all industrial product transfer installations.

Working pressure see additional info. Temperature range – 20° C up to + 80° C; fulfillment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

Heavy Duty Swivels - double ball race

Compact swivel, to allow free rotation of a handling device to protect a hose from torsion.

Typically mounted at one of the ends of a hose where handling equipment without integrated swivel is attached where rotation of adjacent equipment is expected.

Suitable for all common liquid and gaseous media in all industrial product transfer installations.

Working pressure see additional info. Temperature range – 20° C up to + 80° C; fulfillment of larger temperature range – 50° C up to + 200° C is possible – depending on medium, coupling and seal material.

The Dry Gas Coupling has been developed for a safe quick connection and disconnection of hoses and loading arms to tank trucks, rail tankers and tank containers. During connection and after disconnection there is no spillage. MannTek Dry Gas Coupling for safe handling of LPG- in liquid or vapar phases. This increases safety in loadingprocess of hazardous fluids.The robust design ,easy servicing and high level of security assures safe and frequent use on a long term basis.

Dry Gas Coupling function

To Connect

Push and turn

-It´s coupled

-full flow

To disconnect

Turn and pull

-It´s realised

-no spillage

Tank unit, with integrated shut-off valve, to EN 13760 / EN 13175. Self locking quick connect/disconnect coupling for the loading and unloading of liquefied petroleum gas LPG and various other media. Typically fix mounted as filling connector on storage tanks, mobile tanks, road tankers, rail tankers, containers and ship manifolds.

DN 25 as LPG fuelling connector for heavy duty vehicles to EN 13760.

DN 50 as LPG filling connector for trucks on liquid line or as vapor return on railcars to EN 13175 up to + 80° C; Low Temperature version down to -50°C available.

DN 80 as LPG filling connector for railcars on liquid line to EN 13175.

Can be coupled up to 15 bar and uncoupled up to 25 bar. Working pressure PN 25 bar. Temperature range -20° C up to +80° C; Low Temperature version down to -50°C available.

Female (Hose Unit, Coupler)

Hose unit with swivel, with integrated shut-off valve, to EN 13760 / EN 13175. Self locking quick connect/disconnect coupling for the loading and unloading of liquefied petroleum gas LPG and various other media.

Typically mounted on hose assemblies and loading arms for temporary connection between storage tank and mobile transport units.

DN 25 as LPG fuelling connector for heavy duty vehicles to EN 13760.

DN 50 as LPG filling connector for trucks on liquid line or as vapor return on railcars to EN 13175

DN 80 as LPG filling connector for railcars on liquid line to EN 13175.

Can be coupled up to 15 bar and uncoupled up to 25 bar. Working pressure PN 25 bar. Temperature range – 20° C up to + 80° C; Low Temperature version down to -50°C available.

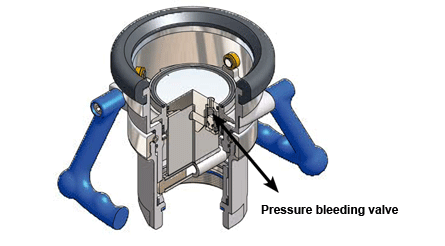

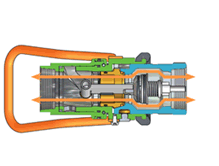

The Dry Cryogenic Coupling (LNG coupling) consist of a “tank” unit wich is a type of a non-return valve and a “hose” unit with a valve driven by an internal cam curve to open both valves at the same time. Operation is a single action using a straight forward turning motion to connect the couplings and open flow path. An initial push and turn action on the hose unit provides engagement with the tank unit, thus locking and sealing the two units together. Further rotation opening the internal valves, thereby allowing full flow with a minimum of pressure drop.

Technical information for Dry Cryogenic Couplings

- Coupling Sizes

1″ (DN25) to 8” (DN200) - Working pressure

MWP 25 Bar – 1″ (DN25) to 4″ (DN100)

MWP 16 Bar – 6″ (DN150) to 8″ (DN200)or - Connections

Female NPT, flanged EN and ANSI.

Others on request.

Advantages with Dry Cryogenic Couplings, MannTek LNG Couplings

- Easy to handle

Push and turn – free flow.

Turn and pull – closed. - Safe

The valve cannot be opened until the unit is coupled and closes automatically when disconnecting.

- Environmentally friendly

Accidental spillage eliminated. - Reliability

No loss or spillage of liquids at connection or disconnection.

Tank unit, with integrated shut-off valve, to ISO TS 18683. Self locking quick connect/disconnect coupling for the loading and unloading of cryogenic liquefied gases down to -196° C.

Typically fix mounted as filling connector for container discharge, fuel bunkering truck-to-ship, ship-to-ship, terminal-to-ship, loading/unloading of tank trucks, rail tankers and bunkering.

Can be coupled up to 7 bar. Working pressure DN 25-DN100: PN 25 bar, DN 150: PN 16 bar. Temperature range – 196° C up to +85°C.

Hose unit with swivel, with integrated shut-off valve, to ISO TS 18683. Self locking quick connect/disconnect coupling for the loading and unloading of cryogenic liquefied gases down to -196° C.

Typically mounted on hose assemblies and loading arms for temporary connection between storage tank and mobile transport units, e.g. for container discharge, fuel bunkering, loading/unloading of tank trucks, rail tankers and bunker vessels

Can be coupled up to 7 bar. Working pressure DN 25-DN100: PN 25 bar, DN 150 mm: PN 16 bar. Temperature range – 196° C to +85°C.