We provide you with Loading Terminal Products from FOR TVALE™.

Petroleum Handling Equipment

Safeload Semi-Automatic API Coupler

Safeload Semi-Automatic API Coupler – Designed for

bottom loading with a unique wrap-around trigger design

that follows the profile of the loading adaptor, covering

more than 60% of its circumference.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel operating handle as standard. Operating instructions included. Seal options – See Range

Options – High pressure version. Manually operated version. Available with ball-end aluminium handle

Features & Benefits

Bumper ring protects against glancing blows.

3 Year Warranty on all metal parts.*

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Instant “snap on” fixture to tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

SAFELOAD will not open unless connected

correctly nor uncouple until fully closed.

Compression spring energised main seal.

All seals may be replaced in-situ using the correct

tools and procedure.

Wear critical components tested to simulate

over 5 years continual service.

Safeload Semi-Automatic High-Pressure API Coupler

Safeload Semi-Automatic High-Pressure API Coupler –

Designed for bottom loading with a unique wrap-around

trigger design that follows the profile of the loading

adaptor, covering more than 50% of its circumference.

Incorporating an interlock safety latch.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel operating handle as standard. Operating instructions included. Seal options – See Range

Options – Standard 6 Bar semi-automatic version. Manually operated version. Available with ball-end aluminium handle.

Features & Benefits

Interlock latch prevents accidental actuation if

the coupler is subject to lateral impact.

3 Year Warranty on all metal parts.*

Handle to body interlock ensures that

SAFELOAD will not open unless connected

correctly nor uncouple until fully closed.

Strengthened steel collar ensures a robust latch

engagement with the outer collar, reducing

wear and increasing safety.

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Instant “snap on” fixture to tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

Internal main actuating springs are not

vulnerable to damage or corrosion.

Compression spring-energised main seal offers

longevity of service.

Wear critical components tested to simulate over

5 years continual service.

Trigger design allows full alignment and

connection even if loading arms are crossed

over.

Safeload Manual API Coupler

Safeload Manual API Coupler – Designed for bottom

loading with a unique wrap-around trigger design that

follows the profile of the loading adaptor, covering more

than 60% of its circumference.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel handle as standard. Operating instructions included. Seal options – See Range

Options – Semi-automatic and high-pressure versions. Available with ball-end aluminium handle.

Features & Benefits

3 Year Warranty on all metal parts.*

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

SAFELOAD will not open unless correctly

connected and may not be uncoupled until fully

closed.

Compression spring energised main seal.

All seals may be replaced in-situ using the correct

tools and procedure.

New trigger design also stops the twist if arms

are crossed over, keeping the coupler nose in

line with the adaptor.

The new shaft and nut assembly is easier to

maintain.

The new double seal arrangement stops dirt

from entering the seal pocket.

4” TTMA Check Valve

The 4” TTMA Check Valve with fluid transfer hole suits the 4” Safeload range of bottom loading couplers. It is designed for use on a flexible hose as a secure secondary closure – i.e. the Safeload coupler may be removed from the loading arm for maintenance without needing to drain the hose fully, thereby reducing loss of fuel. The Safeload Check valve also prevents fraudulent gravity drainage and theft of the fuel in the loading arm. Inlet flange (hose connection) drilled 8 x 11mm holes equi-spaced on a 149.2mm PCD (4”TTMA). Manufactured in aluminium and stainless steel, fitted with Viton B seal as standard. Options – Alternative seal materials available. Spring pressure options dependant upon static head pressure in the hose.

4” API Coupler Seal Replacement Tool

4” API Coupler Seal Replacement Tool – this tool may be used to assist the replacement of the spindle seals and seal carrier seals on a 4” API Coupler either in-situ on the loading gantry or dismantled from the loading gantry. Weight 4.5 Kg

Safeload Loading Arm System

The Fort Vale 4″ Safeload Loading Arm System consists of a combination of top-quality components, each with unique design features. Designed, manufactured and tested in-house, the Safeload System can be configured to produce a top or bottom loading arm solution. Unique to the market, the balance mechanism is manufactured in stainless steel, ensuring excellent corrosion resistance and inherent strength and durability. Balance adjustment is controlled by gas springs and a limiter bolt provides failsafe damage protection. All swivels have an integral earth system that ensures electrical continuity, eliminating the necessity for separate earth wiring. Specialist PTFE seals are fitted throughout, offering excellent chemical resilience and a high resistance to

extrusion and splitting in service. The intermediate and coupler swivels are available in

stainless steel or aluminium. A variety of spools and drop hoses are available for maximum installation flexibility and we offer a range of Safeload API bottom loading couplers to suit your

operating requirements.

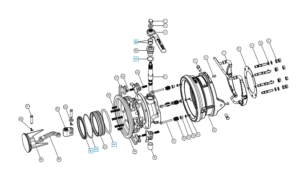

Safeload Loading Arm Components

Safeload Balance Mechanism Assembly

The balance mechanism is manufactured in stainless steel which ensures excellent corrosion resistance and inherent strength and durability. Balance adjustment is controlled by gas springs, which are considered a safer and more reliable option than compression springs. A limiter bolt is incorporated as a failsafe to protect the loading arm from damage in the unlikely event of gas spring de-pressurisation. For ultimate installation flexibility, the balance mechanism can be configured to suit a top or bottom fuel supply as well as left or right orientation.Please see below for details about Safeload swivel

assemblies.

Safeload Base Swivel Assembly

The base swivel assembly incorporates a superior 3-seal and dual needle/dual ball race bearing combination for maximum axial and radial strength and performance. The specialist PTFE primary seal is rated to 400 BarG, so is less prone to extrusion and splitting in high-pressure operating conditions. It is highly resistant to deterioration caused by product contact and affords the operator low-friction ease of movement. PTFE secondary and tertiary seals protect the swivel mechanism from dirt ingress, ensuring a long-lasting and hard-working installation.

An optional “swivel stop” device is available separately which prevents radial over-rotation and collision with adjacent loading arms. An integral earth system ensures electrical continuity,

eliminating the need for separate earth wiring.

Safeload Intermediary Swivel & Coupler Swivel

As a superior safety feature, all swivels contain an integral earth system, unique to the Safeload design, that ensures electrical continuity and eliminates the need for separate earth wiring.

Intermediate and coupler swivels are available in stainless steel or aluminium. A variety of spools and drop hoses are available.All swivel/pipework flanges have industry standard drilling

patterns to be compatible with existing terminal installations. Intermediate Swivel Part Number

Stainless steel – 94/7125

Aluminium – 94/7025

Coupler Swivel Part Number

Stainless steel – 94/7120X

Aluminium – 94/7020X