KFE provides pneumatically operated footvalves in 4″ & 3″. There are models that cover all height requirements, normal profile KLM4HP, low profile valves KLM4LP and very low profile KLM4ULP. The KFE footvalves are available in variants for sequential and non-sequential functioning and are constructed using quality materials such as aluminum alloys and Viton seals. All footvalves are tested and certified according to the European Standard EN13308 while on production is followed a strict quality control program that includes 100% control in hydraulic test and leak test.

The emergency footvalves are necessary safety equipment for all Class 3 fuel road tankers. The KFE footvalves are available in 3″ and 4″ in all standard sizes and sequential and non-sequential operation. KFE footvalves meet the requirements of EN13308 standards and undergo strict quality control system, which ensures trouble free operation throughout the duration of the planned lives.

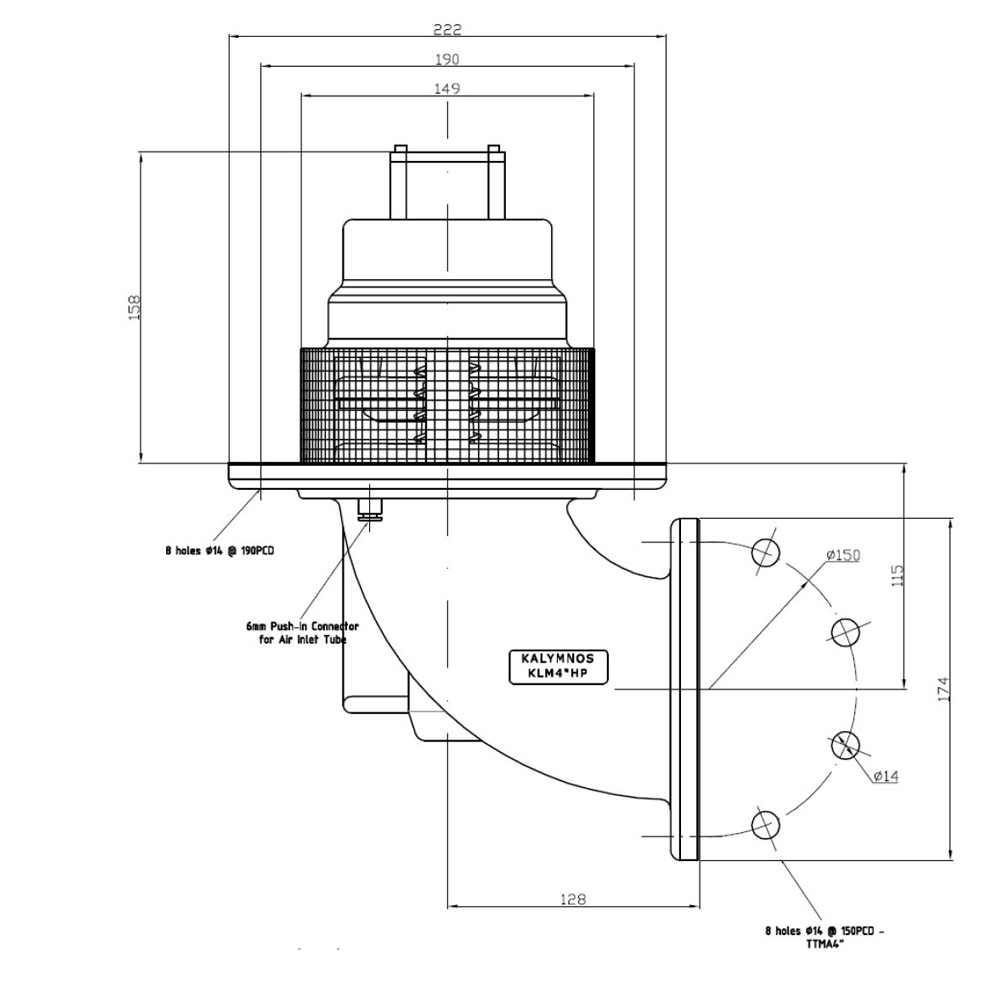

KLM4HP - 4” Pneumatic Emergency Bottom Valve

Product Description

Innovative design, ease of maintenance, and durability are the key benefits of the KLM emergency bottom valve series. Covering a wide range of profiles and functionalities KLM series provides complete solution for every ADR fuel tanker application.

– High flow low pressure drop design for increased discharge rates.

– Standard Valve Profile for easy installation

– Robust construction of the sell made of aluminium alloy tested for sell strength at 25bar.

– Conforms to European Standard EN13308:2002 for the Non-Pressure Balanced Valve

– Viton seals are standard for problem free service with high octane unleaded petrol and additives.

– Shear Groove for increased safety.

– Manual Opening ability for emergency discharge of cargo.

– Strainer fitted as standard to prevent seal damage.

– TTMA 4″ pipe flange for secure connection…

– Sequential and Non Sequential variations available covering all needs.

Technical Data

MWP: 500 kPa

Valve Weight: 5.8 kg Non-Pressure Balanced

Test Pressure: 775 kPa

Downloads

[wpdm_package id=1982 template=”57d7af918045b”]

Video Data

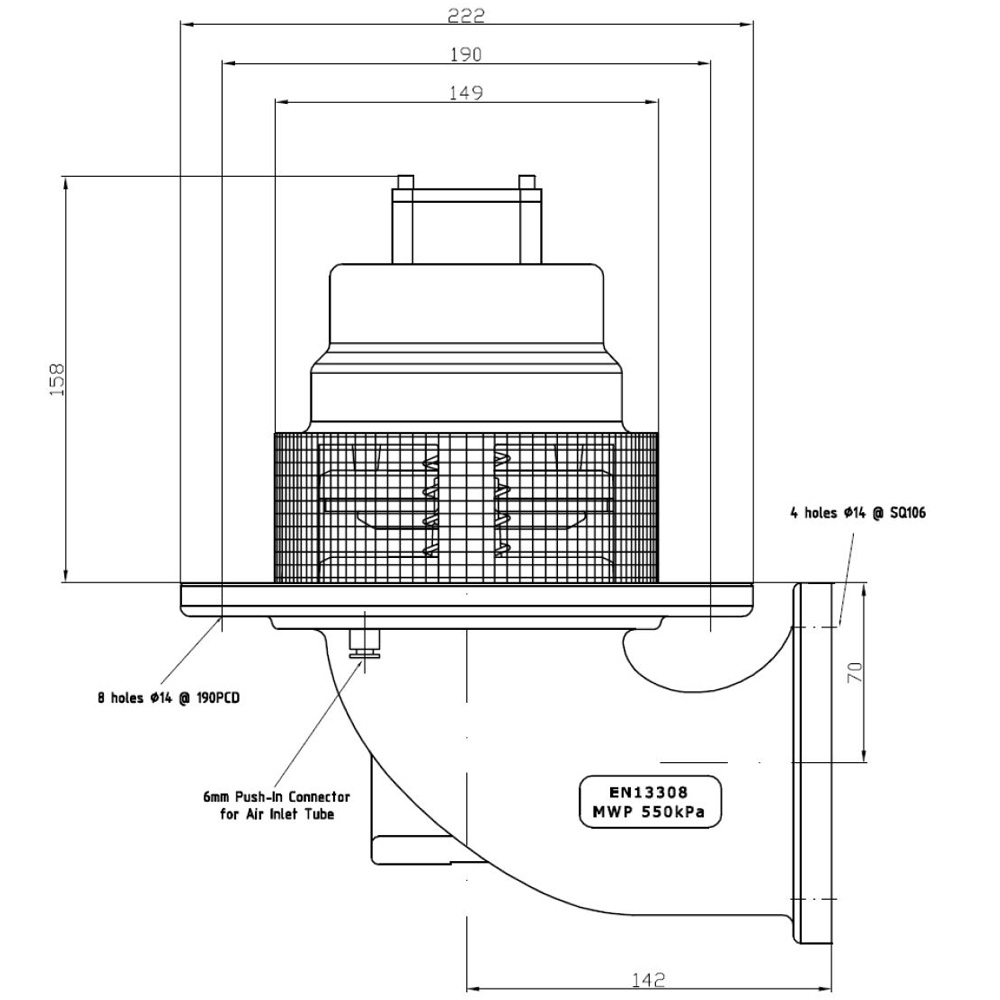

KLM4LP - 4" Pneumatic Emergency Bottom Valve – Low Profile

Product Description

Innovative design, ease of maintenance, and durability are the key benefits of the KLM emergency bottom valve series. Covering a wide range of profiles and functionalities KLM series provides complete solution for every ADR fuel tanker application.

– High flow low pressure drop design for increased discharge rates.

– Low Valve Profile for easy installation in confined spaces.

– Robust construction of the sell made of aluminium alloy tested for sell strength at 25bar.

– Conforms to European Standard EN13308:2002 for non-pressure balanced bottom valves.

– Viton seals are standard for problem free service with high octane unleaded petrol and additives.

– Shear Groove for increased safety.

– Manual Opening ability for emergency discharge of cargo.

– Strainer fitted as standard to prevent seal damage.

– TW3- 4″ pipe flange for secure connection.

– Sequential and Non Sequential variations available covering all needs.

Technical Data

MWP: 500 kPa

Valve Weight: 5.6 kg Non-Pressure Balanced

Test Pressure: 775 kPa

Downloads

[wpdm_package id=1985 template=”57d7af918045b”]

Video Data

KFE provides pneumatically operated footvalves in 4″ & 3″. There are models that cover all height requirements, normal profile KLM4 “HP, low profile valves KLM4″ LP and very low profile SK4 “ULP. The KFE footvalves are available in variants for sequential and non-sequential functioning and are constructed using quality materials such as aluminum alloys and Viton seals. All footvalves are tested and certified according to the European Standard EN13308 while on production is followed a strict quality control program that includes 100% control in hydraulic test and leak test.

The emergency footvalves are necessary safety equipment for all Class 3 fuel road tankers. The KFE footvalves are available in 3″ and 4″ in all standard sizes and sequential and non-sequential operation. KFE footvalves meet the requirements of EN13308 standards and undergo strict quality control system, which ensures trouble free operation throughout the duration of the planned lives.

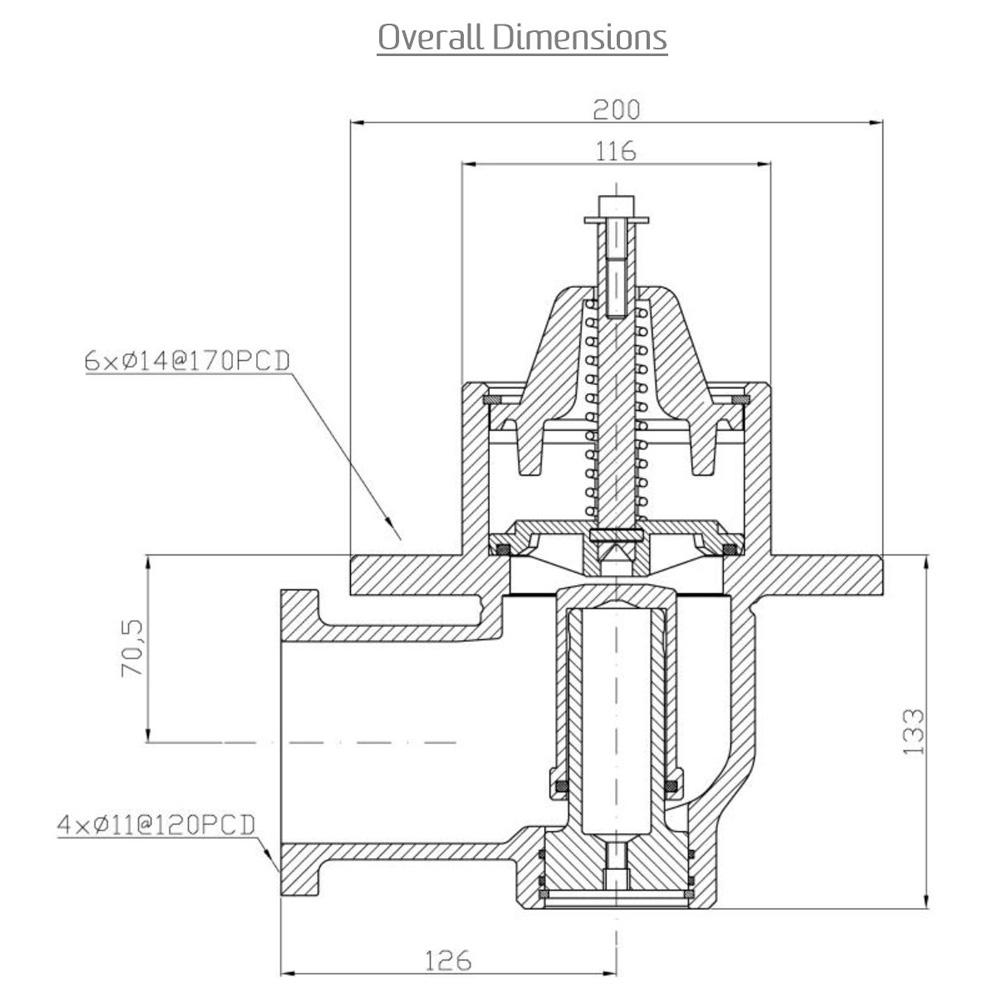

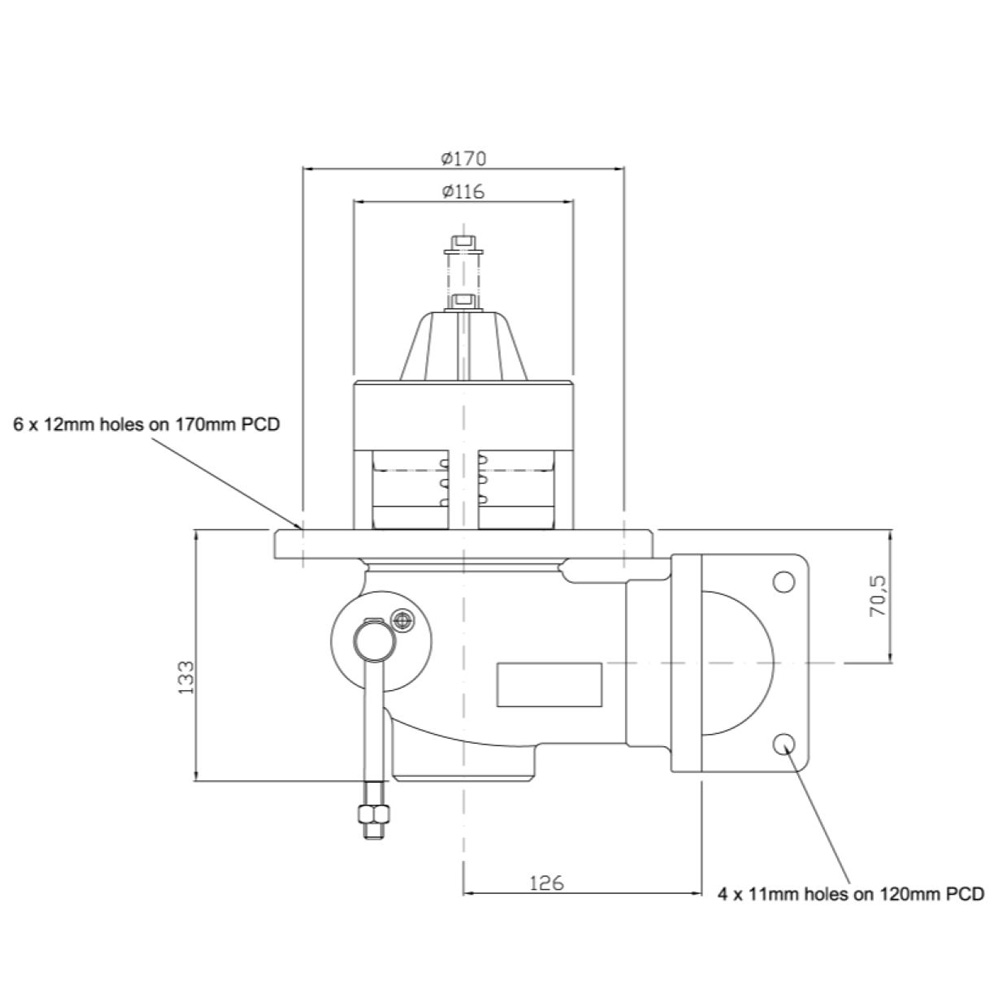

SK3P - 3" Pneumatic Emergency Bottom Valve

Product Description

Ease of maintenance, simplicity of design and durability have helped to make this valve design the first choice of all tank truck manufacturers who require a tough, reliable, pneumatically operated valve in the 3” class.

– High flow low pressure drop design for increased discharge rates.

– Robust construction of the sell made of aluminium alloy tested for sell strength at 25bar.

– Conforms to the European Standard EN13308:2002 and EN16257:2012.

– Viton seals are standard for problem free service with high octane unleaded petrol and additives.

– Shear Groove for increased safety.

– Easily removable bonnet assembly without removing the valve for easy maintenance.

– Easy service, air cylinder design allows replacement without removing the valve from the tank.

Technical Data

MWP : 500 kPa

Valve Weight: 3.8 kgr

Test Pressure: 775 kPa

Downloads

[wpdm_package id=2007 template=”57d7af918045b”]

Video Data

SK3M - 3” Mechanical Emergency Bottom Valve

Product Description

Ease of maintenance, simplicity of design and durability have helped to make this valve design the first choice of all tank truck manufacturers who require a tough, reliable, mechanically operated valve in the 3” class.

– High flow low pressure drop design for increased discharge rates.

– Robust construction of the sell made of aluminium alloy tested for sell strength at 25bar.

– Conforms to AFBOR NF M88-118 standard in valve design.

– Type tested according to European Standard EN13308:2002.

– Viton seals are standard for problem free service with high octane unleaded petrol and additives.

– Shear Groove for increased safety.

– Easily removable bonnet assembly without removing the valve for easy maintenance.

Technical Data

MWP: 500 kPa

Valve Weight: 4.2 kgr

Test Pressure: 775 kPa

Downloads

[wpdm_package id=2009 template=”57d7af918045b”]

Video Data

In addition to the footvalves KFE provides a range of welding flanges for the bottom of the tank compartment. Welding sumps and flanges are available. The materials can be steel, aluminum or stainless steel.

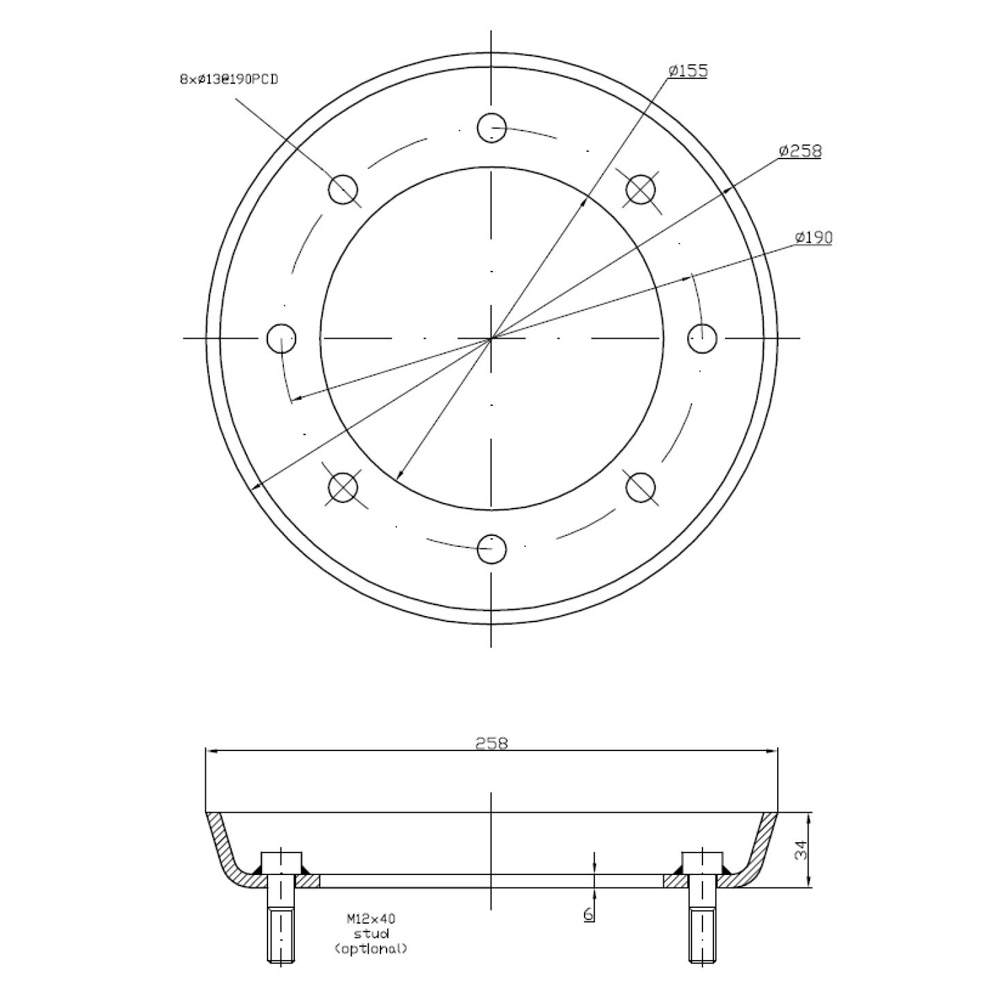

BVS100St/Al - Welding Sump for Bottom Valves

Product Description

The BVS100St/Al welding sump covers the demands for the installation of emergency bottom valves on the tank bottom and offers unrivalled design and installation features.

– 8 Bold Installation Interface covers the demands of EN13308 and EN13314.

– Material Selection is suitable for the weldability with steel or aluminum tanks.

– BVS100St version from S235JR Steel.

– BVS100Al version for EN AW5083-H111.

– Marking of each individual neckring assures the tank builder for the quality and traceability of the installed material.

– Wide Flat Sealing Surface allows for correct sealing and proper installation of bottom valves.

– M12x40 8.8 Studs preinstalled complete with nuts and lock washers for easy installation.

– Suitable for Aluminum or Steel ADR Class 3 tanks for carrying dangerous goods with a vapour pressure not exceeding 110kPa@50oC (absolute pressure).

Technical Data

Material: S235JR (St) / EN AW5083-H111 (Al)

Thickness: 6 mm (St) / 8 mm (Al)

Downloads

[wpdm_package id=2027 template=”57d7af918045b”]

Video Data

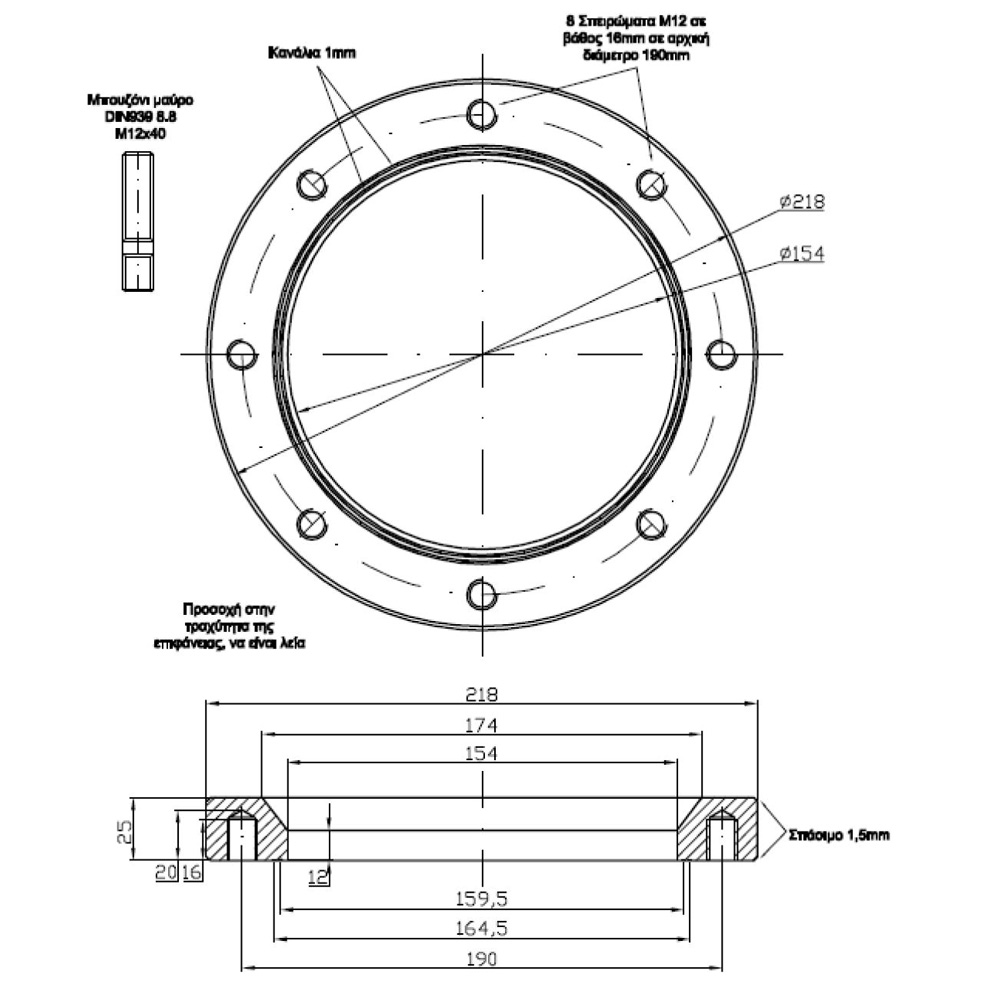

BVF100St/Al - Welding Flange for Bottom Valves

Product Description

The BVF100St/Al welding flange covers the demands for the installation of emergency bottom valves on the tank bottom and offers unrivalled design and installation features.

– 8 Bold Installation Interface covers the demands of EN13308 and EN13314.

– Material Selection is suitable for the weldability with steel or aluminum tanks.

– BVF100St version machined from S235JR Steel.

– BVF100Al version machined from hard drown aluminum bar.

– Marking of each individual neckring assures the tank builder for the quality and traceability of the installed material.

– Wide Flat Sealing Surface allows for correct sealing and proper installation of bottom valves.

– Internal Wide Chamfer allows for unrestricted flow from the bottom valve.

– M12x40 8.8 Studs preinstalled complete with nuts and lock washers for easy installation.

– Suitable for Steel or Aluminum ADR Class 3 tanks for carrying dangerous goods with a vapour pressure not exceeding 110kPa@50oC (absolute pressure).

Technical Data

Material: S235JR (St)

Thickness: 25 mm (St) / 30 mm (Al)

Downloads

[wpdm_package id=2030 template=”57d7af918045b”]

Video Data

For the operation of the mechanical footvalves KFE manufactures mechanical controls for tanks with 1 to 6 apartments. Mechanical controls KFE are robust in construction and feature integrated melting link for the automatic sealing of the tank compartments in case of fire.

SK21030 - 3 Compartment Bottom Valve Operator

Product Description

Simple and robust construction gives to the SK 21.030 Bottom Valve Operator the benefit for a long life service. Incorporated safety features ensure maximum safety during product discharge.

– Fusible link will operate and shut down the system in case of fire.

– Manual Shut Down in case of emergency is available as a standard feature.

– CNC Laser Cut components of the operator for assured dimensional accuracy.

– Durable construction from galvanized mild steel.

– Full Range from one to six Bottom Valves available.

Technical Data

Number of Compartments: 1 to 6

Operator Weight: 2 kg

Downloads

[wpdm_package id=2050 template=”57d7af918045b”]