Fort Vale Engineering Limited is the world leader in the precision manufacture of valves and fittings for the transportation of bulk liquids in the tank container, road tanker and rail industries. The transportation of gases and liquids by road, rail and sea must be safe and Fort Vale works with the industry and regulatory bodies so that the quality of its design, materials and manufacture ensures that first-class safety is a reality.

The company goal is not only to be the preferred supplier of new OEM equipment but also the premier after-sales supplier for spares. To this end Fort Vale has offices and stock in the UK, USA, Holland, Singapore, China and Russia, as well as authorised distributors located around the world.

We provide you with Loading Terminal Products from FOR TVALE™.

Petroleum Handling Equipment

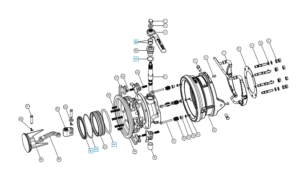

Safeload Semi-Automatic API Coupler

Safeload Semi-Automatic API Coupler – Designed for

bottom loading with a unique wrap-around trigger design

that follows the profile of the loading adaptor, covering

more than 60% of its circumference.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel operating handle as standard. Operating instructions included. Seal options – See Range

Options – High pressure version. Manually operated version. Available with ball-end aluminium handle

Features & Benefits

Bumper ring protects against glancing blows.

3 Year Warranty on all metal parts.*

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Instant “snap on” fixture to tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

SAFELOAD will not open unless connected

correctly nor uncouple until fully closed.

Compression spring energised main seal.

All seals may be replaced in-situ using the correct

tools and procedure.

Wear critical components tested to simulate

over 5 years continual service.

Safeload Semi-Automatic High-Pressure API Coupler

Safeload Semi-Automatic High-Pressure API Coupler –

Designed for bottom loading with a unique wrap-around

trigger design that follows the profile of the loading

adaptor, covering more than 50% of its circumference.

Incorporating an interlock safety latch.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel operating handle as standard. Operating instructions included. Seal options – See Range

Options – Standard 6 Bar semi-automatic version. Manually operated version. Available with ball-end aluminium handle.

Features & Benefits

Interlock latch prevents accidental actuation if

the coupler is subject to lateral impact.

3 Year Warranty on all metal parts.*

Handle to body interlock ensures that

SAFELOAD will not open unless connected

correctly nor uncouple until fully closed.

Strengthened steel collar ensures a robust latch

engagement with the outer collar, reducing

wear and increasing safety.

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Instant “snap on” fixture to tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

Internal main actuating springs are not

vulnerable to damage or corrosion.

Compression spring-energised main seal offers

longevity of service.

Wear critical components tested to simulate over

5 years continual service.

Trigger design allows full alignment and

connection even if loading arms are crossed

over.

Safeload Manual API Coupler

Safeload Manual API Coupler – Designed for bottom

loading with a unique wrap-around trigger design that

follows the profile of the loading adaptor, covering more

than 60% of its circumference.

4” TTMA inlet flange. Outlet connection complies with API RP 1004. Materials of construction – hard anodised aluminium, nitrided steel and stainless steel. Fitted with Viton B seals and stainless steel handle as standard. Operating instructions included. Seal options – See Range

Options – Semi-automatic and high-pressure versions. Available with ball-end aluminium handle.

Features & Benefits

3 Year Warranty on all metal parts.*

Tapered lead-in of coupler ensures failsafe

alignment with tank adaptor.

Four wrap-around extended triggers lock the

coupler securely in place.

SAFELOAD will not open unless correctly

connected and may not be uncoupled until fully

closed.

Compression spring energised main seal.

All seals may be replaced in-situ using the correct

tools and procedure.

New trigger design also stops the twist if arms

are crossed over, keeping the coupler nose in

line with the adaptor.

The new shaft and nut assembly is easier to

maintain.

The new double seal arrangement stops dirt

from entering the seal pocket.

4” TTMA Check Valve

The 4” TTMA Check Valve with fluid transfer hole suits the 4” Safeload range of bottom loading couplers. It is designed for use on a flexible hose as a secure secondary closure – i.e. the Safeload coupler may be removed from the loading arm for maintenance without needing to drain the hose fully, thereby reducing loss of fuel. The Safeload Check valve also prevents fraudulent gravity drainage and theft of the fuel in the loading arm. Inlet flange (hose connection) drilled 8 x 11mm holes equi-spaced on a 149.2mm PCD (4”TTMA). Manufactured in aluminium and stainless steel, fitted with Viton B seal as standard. Options – Alternative seal materials available. Spring pressure options dependant upon static head pressure in the hose.

4” API Coupler Seal Replacement Tool

4” API Coupler Seal Replacement Tool – this tool may be used to assist the replacement of the spindle seals and seal carrier seals on a 4” API Coupler either in-situ on the loading gantry or dismantled from the loading gantry. Weight 4.5 Kg

Safeload Loading Arm System

The Fort Vale 4″ Safeload Loading Arm System consists of a combination of top-quality components, each with unique design features. Designed, manufactured and tested in-house, the Safeload System can be configured to produce a top or bottom loading arm solution. Unique to the market, the balance mechanism is manufactured in stainless steel, ensuring excellent corrosion resistance and inherent strength and durability. Balance adjustment is controlled by gas springs and a limiter bolt provides failsafe damage protection. All swivels have an integral earth system that ensures electrical continuity, eliminating the necessity for separate earth wiring. Specialist PTFE seals are fitted throughout, offering excellent chemical resilience and a high resistance to

extrusion and splitting in service. The intermediate and coupler swivels are available in

stainless steel or aluminium. A variety of spools and drop hoses are available for maximum installation flexibility and we offer a range of Safeload API bottom loading couplers to suit your

operating requirements.

Safeload Loading Arm Components

Safeload Balance Mechanism Assembly

The balance mechanism is manufactured in stainless steel which ensures excellent corrosion resistance and inherent strength and durability. Balance adjustment is controlled by gas springs, which are considered a safer and more reliable option than compression springs. A limiter bolt is incorporated as a failsafe to protect the loading arm from damage in the unlikely event of gas spring de-pressurisation. For ultimate installation flexibility, the balance mechanism can be configured to suit a top or bottom fuel supply as well as left or right orientation.Please see below for details about Safeload swivel

assemblies.

Safeload Base Swivel Assembly

The base swivel assembly incorporates a superior 3-seal and dual needle/dual ball race bearing combination for maximum axial and radial strength and performance. The specialist PTFE primary seal is rated to 400 BarG, so is less prone to extrusion and splitting in high-pressure operating conditions. It is highly resistant to deterioration caused by product contact and affords the operator low-friction ease of movement. PTFE secondary and tertiary seals protect the swivel mechanism from dirt ingress, ensuring a long-lasting and hard-working installation.

An optional “swivel stop” device is available separately which prevents radial over-rotation and collision with adjacent loading arms. An integral earth system ensures electrical continuity,

eliminating the need for separate earth wiring.

Safeload Intermediary Swivel & Coupler Swivel

As a superior safety feature, all swivels contain an integral earth system, unique to the Safeload design, that ensures electrical continuity and eliminates the need for separate earth wiring.

Intermediate and coupler swivels are available in stainless steel or aluminium. A variety of spools and drop hoses are available.All swivel/pipework flanges have industry standard drilling

patterns to be compatible with existing terminal installations. Intermediate Swivel Part Number

Stainless steel – 94/7125

Aluminium – 94/7025

Coupler Swivel Part Number

Stainless steel – 94/7120X

Aluminium – 94/7020X

We provide you with Chemical Tanker Products from FORT VALE™.

MANLID EQUIPMENT

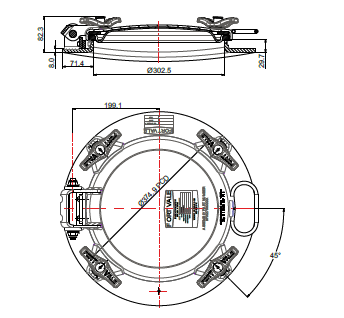

300mm Ultra Low Profile EN Pendle

Inspection Hatch Assembly

300mm Ultra Low Profile Inspection Hatch Assembly – 4 point fastening double skin cover. 8mm thick pressed neck/compensating ring profiled to suit tank radius range from 850 to 1220mm. Contact parts manufactured in 316 stainless steel. Stainless steel swingbolts with naval brass handnuts. Seal supplied separately. Options – Stainless steel swingbolts with either stainless steel handnuts or low profile stainless steel/brass composite handnuts.

Specification

Weight 19.8 Kg *See Note

Design Pressure (MAWP) 4 Bar (58 PSI)

Test Pressure 6 Bar (87 PSI)

Design Temperature -40°C to 200°C

(-40°F to 392°F)

*NB Above data varies according to specification

Manlid cover 703/0600P approved to BS EN14025

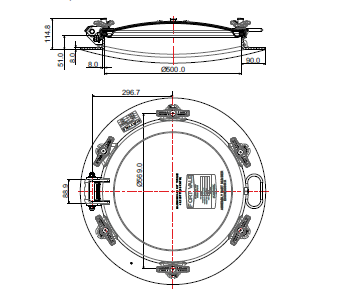

500mm Pendle 3 Bar Manlid/ Deep Pressed Neck Assembly

500mm Pendle Manlid Assembly – 6 point double skin manlid cover, hinged to open to 135°. Deep pressed neck/compensating ring, 51mm in height, profiled to suit a tank radius of between 850mm and 1220mm. To suit a MAWP of 3 Bar. Contact parts manufactured in 316 stainless steel with stainless steel swingbolt assemblies. Seal supplied separately.

AIRLINE VALVES

2” Pneumatic Blacko Ball Valve

2” Pneumatically Operated Air Inlet Ball Valve – inlet flange drilled 4 x 18mm holes on a 125mm PCD; outlet flange 4 x 18mm open slots on a 120.7mm minimum PCD to suit 2” ASA 150/DIN50 PN40. Valve manufactured in 316 stainless steel with PTFE seals. Fitted with Kinetrol

pneumatic actuator with spring return and ¼” BSP air inlet.

Specification

Weight 5.88 Kg

Design Pressure (MAWP) 7 Bar (101.5 PSI)

Test Pressure 15 Bar (217.5 PSI)

Design Temperature: Valve -40°C to 205°C

(-40°F to 400°F)

Kinetrol Actuator -20°C to 80°C

(-4°F to 176°F)

Ball valve approved to BS EN 14432.

1” BSP Pressure Only Minnow IBC Relief Valve

1”BSP Minnow IBC Relief Valve – 1”BSP male connection.

Suitable for a pressure range of between 1 – 45 PSI (0.07 – 3.10 Bar). Contact parts manufactured in 316 stainless steel fitted with Viton seals as standard. Complete with

PTFE tank seal. Options – combined pressure/vacuum version. Alternative seal materials available. Manual vent button option. Ventlock option. 1” BSP female connection available. 1″NPT version.

Specification

Weight 0.18 Kg

Seal Temperature Range :

Viton -20°C to +200°C

Perfluoroelastomer -15°C to +240°C

EPDM -20°C to +150°C

Silicone -20°C to +200°C

Operating Instructions available – OPIN05

Test certificates supplied as standard.

Visual inspection and service (where necessary) is

recommended on a regular basis.

3” 90° Cleanflow Footvalve

3” 90° Cleanflow Footvalve – inlet flange drilled 8 x 14mm holes equi-spaced on a 178mm PCD; outlet flange drilled 4 x 17mm holes equi-spaced on a 160mm PCD with flats milled top and bottom. Contact parts manufactured in 316 stainless steel with Fortyt O ring to main poppet as

standard. Options – different outlet flange configurations available. Alternative seal materials for poppet O ring may be fitted. Conical poppet available for solidifying cargoes. Range

of valves with extended body available. Steam heated option. Pneumatically and hydraulically actuated versions. Full range of 30°, 45° and 180° Cleanflow footvalves. Replaceable Seat version available.

3” 90° Tankstream Footvalve

3” 90° Tankstream Footvalve Options – 3” to 3” 90° footvalve assembly. Inlet flange drilled 12 x14mm holes on a 6.25” PCD. 6 inlet holes are plugged with a plastic plug. Outlet flange drilled 8 x 10.5mm holes on a 124mm PCD. Contact parts manufactured in 316 stainless steel with

Fortyt or Viton O ring. – 3” to 2” footvalve assembly version.

4” 90° Pneumatic “Sealtyt” Extended Footvalve

4” 90° Pneumatic “Sealtyt” Extended Footvalve

-inlet flange drilled 8 x 14mm holes equi-spaced on a 190mm PCD; outlet flange drilled 8 x 14mm holes equi-spaced on a 150.1mm PCD. Manufactured in 316 stainless steel with elastomer core PTFE main seal. Options- hydraulically operated version. TW80 outlet flange drilling available. 4” to 3” option. 105° angled option.

3” Blacko Ball Valve - 3” BSP Outlet

3” Blacko Ball Valve – inlet flange drilled 6 x 14mm holes (see below) on a 168.3mm PCD; 3” BSP male outlet connection. Left hand operated with TIR facility to handle. Contact parts manufactured in 316 stainless steel with PTFE seals. Options – Right hand operation. Steam heated version

Specification

BALL007 REV04-20.04.17 Weight 15.9 Kg Design Pressure (MAWP) 7 Bar (101.5 PSI)

Hydraulic Test Pressure 10.5 Bar (152.3 PSI) Design Temperature Range -40°C to 200°C

(-40°F to 392°F) M12 bolts torque setting : 65 Nm (48 LBF FT) Approved to BS EN14432 & BS EN14025

3” Tank-Pro Road Tanker Butterfly Valve

Designed specifically to meet the needs of the road tanker industry and especially suited to chemical applications. Supplied as a complete unit requiring no extra parts to assemble the valve to the tank. The valve concept eliminates the need for the valve to be centralized when fitting to the tank, thus avoiding potential valve damage and/or leakage. Optional 3/8”BSP port integral to the valve body allows for a purge or sampling facility. Clean valve internal lines reduces the risk of contamination between successive cargoes. Eccentric outlet facilitates full self-draining. Simple maintenance procedure with all internal mechanism and seals common to the standard Fort Vale 3” butterfly valve, thus reducing the required stock of spare parts. Lockable handle with TIR facility as standard to meet ADR requirements. A removable square drive key is included with each valve.

Specification

Weight 6.07 Kgs

Design Pressure 6 Bar (87 PSI)

Body Hydraulic Test Pressure 10 Bar (145 PSI)

Design Temperature -40°C to 200°C

(-40°F to 392°F)

Lloyds Register of Shipping Design Appraisal document

number DCF9376/1. Approved to BS EN14432.

Rijksdienst voor het Wegverkeer Approval number VLG

S-9301.

We provide you with ISO Container Products from FORT VALE™.

CORE SPECIFICATION

4 Bar ISO Tank Container

MANLID EQUIPMENT

The 500mm Pendle manlid assembly is a 4 bar MAWP unit available in 6 or 8 point fastening. The cover is a double skin construction which offers excellent thermal insulation. The assembly has no internal welds as the cover and the neckring with integral compensating ring are each made from a one piece pressed item, reducing corrosion risk and optimizing cleanliness.

Swingbolts are available with naval brass or stainless steel handnuts. All eyebolts are thread rolled and handnuts are fitted with a thrust washer (patented) as standard. Wide range of seals available to suit, including the Super Tanktyt recommended for corrosive and toxic products.

300mm Ultra Low Profile EN Pendle Inspection Hatch Assembly

300mm Ultra Low Profile Inspection Hatch Assembly – 4 point fastening double skin cover. 8mm thick pressed neck/compensating ring profiled to suit tank radius range from 850 to 1220mm. Contact parts manufactured in 316 stainless steel. Stainless steel swingbolts with naval brass handnuts. Seal supplied separately. Options – Stainless steel swingbolts with either stainless steel handnuts or low profile stainless steel/brass composite handnuts.

500mm Ultra Low Profile Pendle Manlid Assembly

500mm Ultra Low Profile Manlid Assembly – 8 point fastening. 8mm thick pressed neck/compensating ring profiled to suit tank radius. Contact parts manufactured in 316 stainless steel. Stainless steel swingbolts with naval brass handnuts. Seal supplied separately.

Options – 3 Bar 6 point version and 4 Bar 8 point version. Tank radius range from 750mm to 1300mm. Stainless steel swingbolts with either stainless steel handnuts or low profile stainless steel/brass composite handnuts. Cover hinge stop plate may be fitted to adjust opening angle.

SAFETY EQUIPMENT

2½” BSP Pressure/Vacuum Super Maxi Relief Valve

2½” BSP Super Maxi Emergency Relief Valve – 2½” BSP male connection with 65mm nominal bore. Suitable for a pressure range of between 2 – 75 PSI (0.14 – 5.17 Bar) and a vacuum range of between 0 – 26”Hg (0 – 0.88 Bar). Contact parts manufactured in 316 stainless steel. Fitted

with Fortyt seals as standard. Complete with rubber/PTFE tank seal.

Options – pressure only version. Flanged connections available. Range of high pressure extended body valves. Manual vent button option. A range of alternative seal materials is available.

82.5mm Flanged Hyper Maxi Pressure/Vacuum Relief Valve

82.5mm Flanged Hyper Maxi Pressure/Vacuum Relief Valve – Flange drilled 4 slots with a 145.0/152.4mm min/max PCD. (See below for drilling details) Suitable for a set pressure range of *2 to 75 PSI (*0.14 to 5.17 Bar) *See Note under Specification, and a set vacuum range of 0.5″Hg to 26″Hg (0.02 to 0.88 Bar). Contact parts manufactured in 316 stainless steel. Fitted with Fortyt

seals as standard.

Options – pressure only version. High pressure extended body version. Alternative seal materials are available. Fort Vale offers a full range of threaded and flanged relief valves.

AIRLINE EQUIPMENT

1½” Blacko Airline Ball Valve

1½” Airline Ball Valve – 1 ½” BSP male inlet. Complete with pressure gauge connection and TIR

facility to handle. Contact parts manufactured in 316 stainless steel with PTFE seals.

Optional extras – gauge guard and/or gauze filter, ¼” BSP plug with TIR wire.

2” BSP Airline Butterfly Valve

2” Airline Butterfly Valve – 2” BSP male inlet. Complete with pressure gauge connection, gauge guard and TIR facility to handle. Contact parts manufactured in 316 stainless steel with PTFE seals.

Optional extras – gauze filter or sintered filters.

MKII 2" Flanged Airline Butterfly Valve

2” Flanged Airline Butterfly Valve – inlet flange slotted to suit 2” BSTD minimum. 4 hole tank connection to DIN50 PN10. Complete with ¼”BSP pressure gauge connection, gauge guard and TIR facility to handle. Contact parts manufactured in 316 stainless steel with PTFE seals.

Optional extras – gauze filter or sintered filter. TIR wire welded to gauge inlet plug.

DISCHARGE EQUIPMENT

3” 45° Cleanflow Footvalve

3” 45° Cleanflow Footvalve – inlet flange drilled 8 x 14mm holes equi-spaced on a 178mm PCD; outlet flange drilling as shown below. Contact parts manufactured in 316 stainless steel with Fortyt O ring to main poppet as standard.

Options – Other poppet seal materials available. Footvalve may be manufactured in other metals. A range of outlet flange configurations available. Conical poppet available for solidifying cargoes. Steam heated option. Available with integral Alloy C276 seat area for corrosive cargoes. Full range of 30°, 90° and 180° Cleanflow footvalves. A range of bolting kits and outlet gaskets is

available.

3” 45° MKIII Highlift Footvalve

3” 45° MKIII Highlift Footvalve – inlet flange drilled 8 x 14mm holes equi-spaced on a 178mm PCD; outlet flange drilled 4 x 17mm holes on a 160mm PCD. Contact parts manufactured in 316 stainless steel with Fortyt main seal as standard.

Options – Other poppet seal materials available. Footvalve may be manufactured in other metals. Full range of 30°, 90° and 180° Highlift footvalves. Steam heated option. Available with integral Alloy C276 seat area. A range of bolting kits and outlet gaskets are available.

3” 45° Uniflow Bottom Discharge Assembly

3” 45° Uniflow Bottom Discharge Assembly – comprising 3” 45° Cleanflow footvalve, inlet flange drilled 8 x 14mm holes equi-spaced on a 178mm PCD; footvalve body incorporates integral 3” butterfly valve terminating with 3” BSP spigot and stainless steel blank cap. Unique “CLEAN” position of butterfly valve closure plate allows for in-situ CIP without removal of the valve assembly from the tank. Manufactured in 316 stainless steel with Fortyt main seal to footvalve and PTFE main seal to butterfly valve and cap.

3” 45° Univalve Bottom Discharge Assembly

3” Univalve Bottom Discharge Assembly – comprising of 3” 45° Highlift footvalve, inlet flange drilled 8 x 14mm holes equi-spaced on a 178mm PCD. Footvalve body incorporates integral 3” butterfly valve terminating with 3” BSP spigot and stainless steel blank cap. Unique “CLEAN” position of butterfly valve closure plate allows for in-situ CIP without removal of the valve assembly from

the tank. Manufactured in 316 stainless steel with Fortyt

main seal to footvalve and PTFE main seal to butterfly

valve and cap.

DISCHARGE EQUIPMENT

3” Clamped Widdop Butterfly Valve

3” Clamped Butterfly Valve – left hand operated with TIR to handle and padlock facility. Contact parts manufactured in 316 stainless steel with PTFE main seal

3” Flanged Widdop Butterfly Valve

3” Flanged Butterfly Valve – inlet flange drilled 6 x 14mm holes spaced as shown below on a 168mm PCD; outlet flange with 4 slots 17mm equi-spaced on a 146mm PCD. Left hand operated with TIR and padlock facility to handle. Contact parts manufactured in 316 stainless steel with PTFE seals.